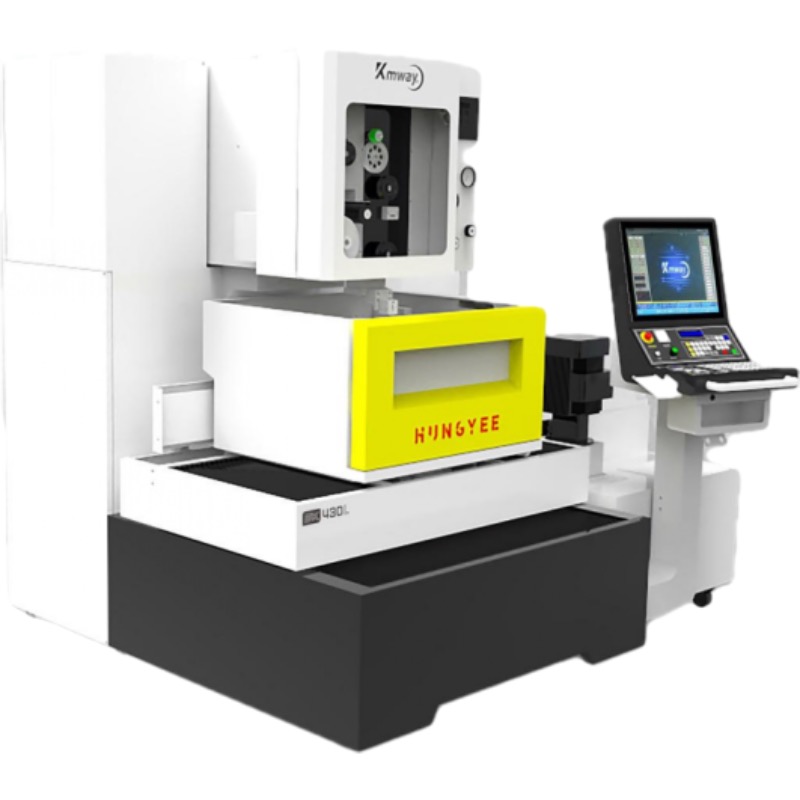

Manufacturing is the backbone of any industrialized nation, driving innovation and economic growth. In the modern era, efficiency and precision are not just desirable—they are essential. This is where Kmway Wire-cut Electrical Discharge Machining (WEDM) machines come into play. Designed to enhance production efficiency and offer unmatched precision, Kmway WEDM machines are revolutionizing manufacturing processes.

How Kmway WEDM Machines Improve Production Efficiency

The Role of Precision Cutting in Modern Manufacturing

Best Practices for Integrating WEDM Machines into Your Production Line

In this blog post, we'll explore how these advanced machines improve production efficiency, the critical role of precision cutting in modern manufacturing, and best practices for integrating WEDM machines into your production line.

How Kmway WEDM Machines Improve Production Efficiency

Kmway WEDM machines are engineered to deliver superior performance and efficiency. One of the primary ways these machines improve production efficiency is through their high-speed cutting capabilities. This enables manufacturers to produce intricate components at a faster rate, significantly reducing production time. Additionally, Kmway WEDM machines are equipped with advanced control systems that ensure consistent quality with minimal manual intervention, thereby reducing the likelihood of human error and increasing overall productivity. Another notable feature of Kmway WEDM machines is their ability to handle a wide range of materials, from soft metals to hard alloys, making them incredibly versatile. This versatility eliminates the need for multiple types of machinery, thereby streamlining the production process and reducing overhead costs. By incorporating Kmway WEDM machines into their operations, manufacturers can achieve a higher output with fewer resources, ultimately leading to improved profitability.

The Role of Precision Cutting in Modern Manufacturing

Precision cutting is a cornerstone of modern manufacturing, and Kmway WEDM machines excel in this area. The ability to cut complex shapes with a high degree of accuracy is crucial for industries such as aerospace, automotive, and medical devices, where even the smallest error can have significant consequences. Kmway WEDM machines use electrical discharges to remove material, allowing for extremely fine cuts that traditional cutting methods cannot achieve. This level of precision ensures that each component meets exact specifications, which is essential for the performance and safety of the final product. Another advantage of precision cutting with Kmway WEDM machines is the reduction of material waste. Traditional cutting methods often result in significant material loss, but the precision of WEDM minimizes this, leading to cost savings and more sustainable manufacturing practices. Furthermore, the surface finish achieved by Kmway WEDM machines is exceptionally smooth, often eliminating the need for secondary finishing processes and thus further improving efficiency.

Best Practices for Integrating WEDM Machines into Your Production Line

Integrating Kmway WEDM machines into your production line can be a game-changer, but it requires careful planning and execution. First, it’s essential to conduct a thorough assessment of your current production capabilities and identify areas where WEDM technology can offer the most significant improvements. Once these areas are identified, proper training for your staff is crucial. Kmway offers comprehensive training programs to ensure that your team can operate the machines efficiently and safely. Additionally, regular maintenance is vital to keep the machines running at optimal performance. Kmway provides detailed maintenance schedules and support services to help you keep your machines in top condition. Another best practice is to start with a pilot project before fully integrating WEDM machines into your entire production line. This allows you to monitor the performance of the machines and make any necessary adjustments without disrupting your entire operation. Finally, leveraging data analytics can help you maximize the benefits of your Kmway WEDM machines. By analyzing performance data, you can identify trends and areas for further optimization, ensuring that you get the most out of your investment.

In conclusion, Kmway WEDM machines offer a powerful combination of speed, precision, and versatility, making them an invaluable asset for any modern manufacturing operation. By improving production efficiency, enhancing precision cutting, and following best practices for integration, manufacturers can achieve significant gains in productivity and profitability. If you’re looking to take your manufacturing capabilities to the next level, consider investing in Kmway WEDM machines.