1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision, and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

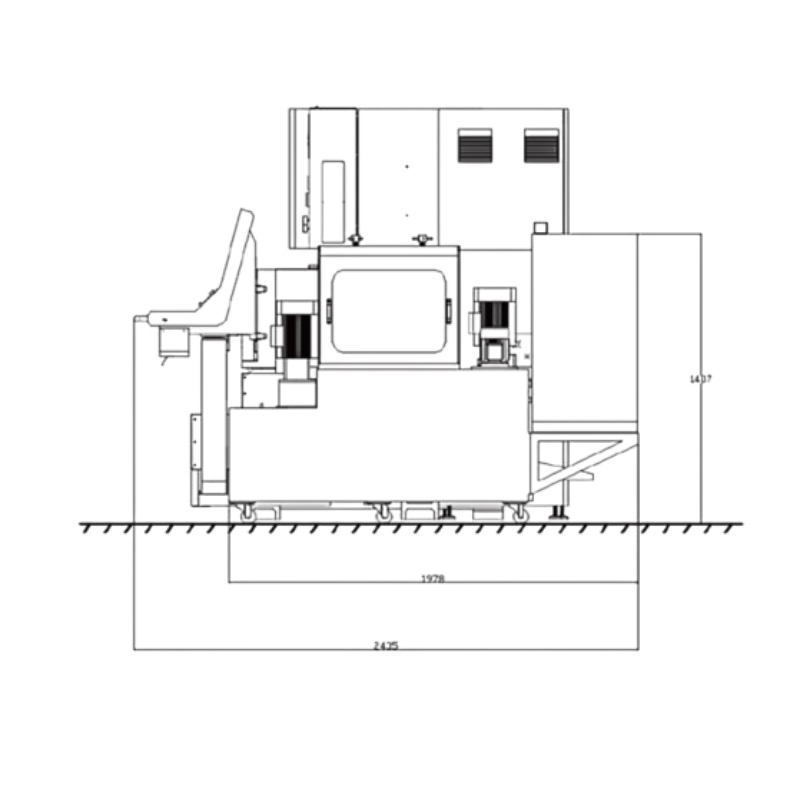

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and we have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

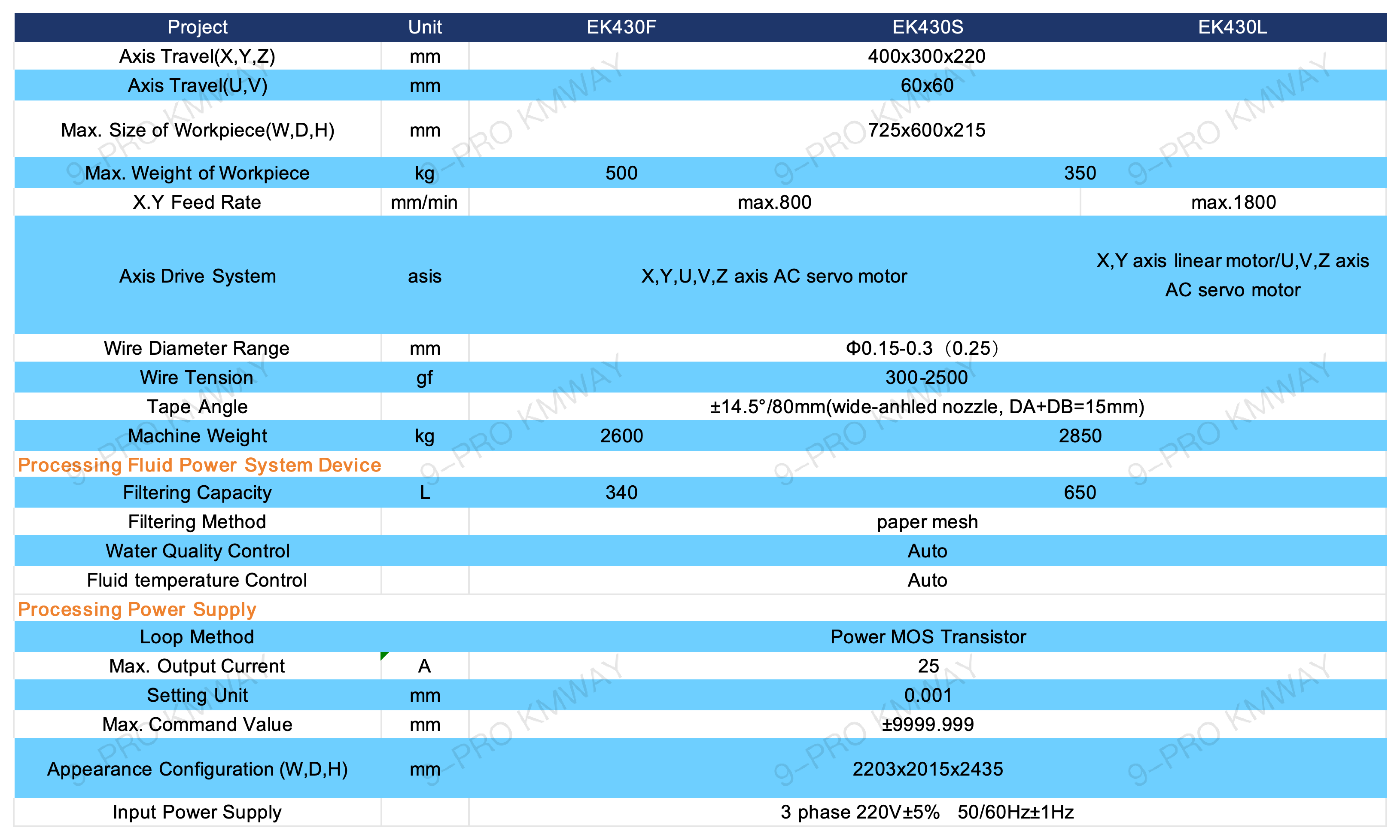

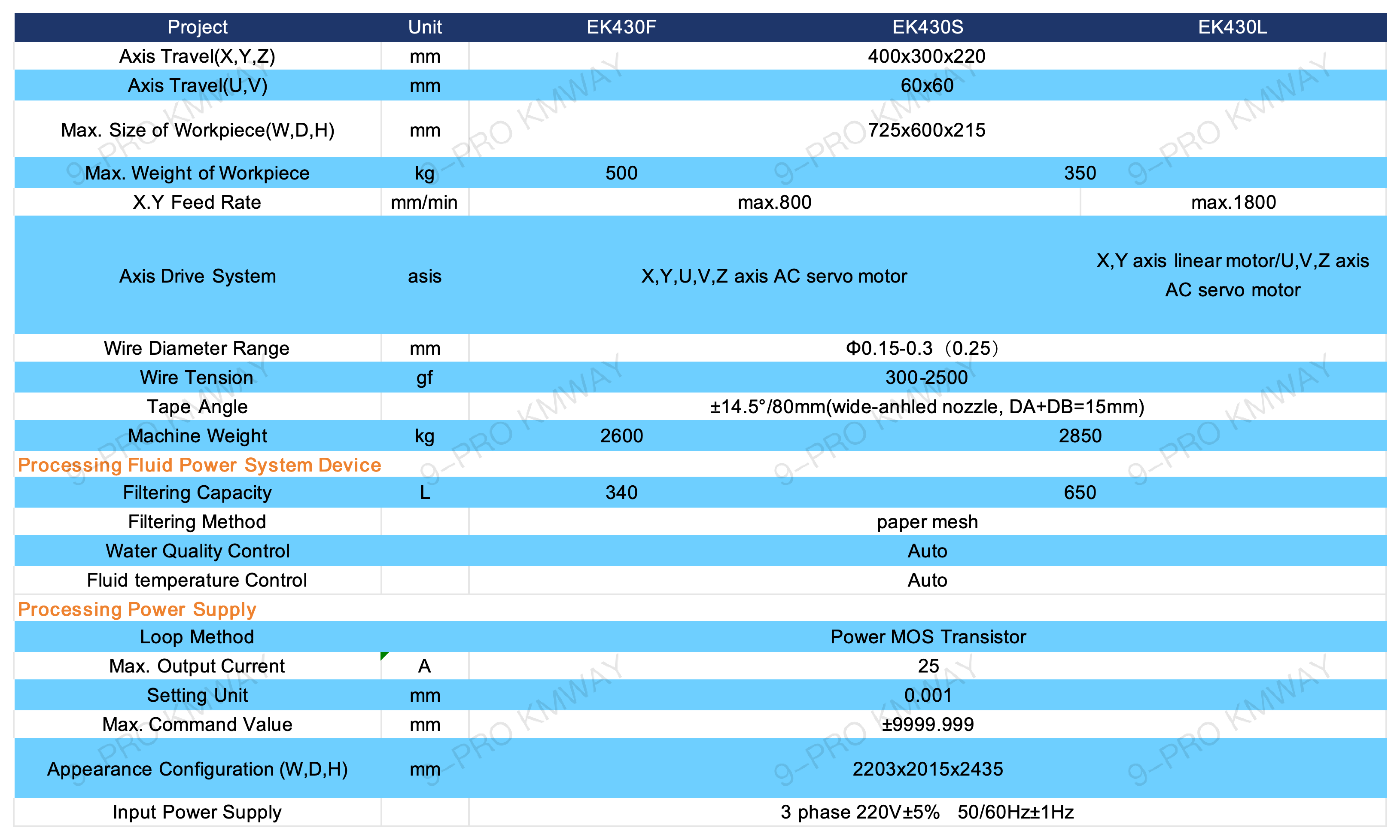

It should be noted that the AWT system of this model needs to be selected, and we will charge a reasonable price.

Note: EK430F cannot select AWT system, EK430S and EK430L can select AWT system, thank you!

1. Kmway uses three vertical water tanks, which contain solenoid valve signal control. It is not like the traditional water tank that starts as soon as water is added, which is more energy-saving.

2. Kmway's air cooler is Gree variable frequency, which is more cost-effective and more energy-saving.

3. Kmway's machines are all integrated, which is more convenient for customers to operate and avoids the trouble of pulling the wires back and forth during work.

4. Kmway provides a one-year extended warranty service for circuit boards for new customers in the region, with a total of two years of warranty.

5. Kmway's automatic threading success rate is higher, and the maintenance of the machine is not as frequent as that of Taiwan's machines, which also saves costs in the later use process.

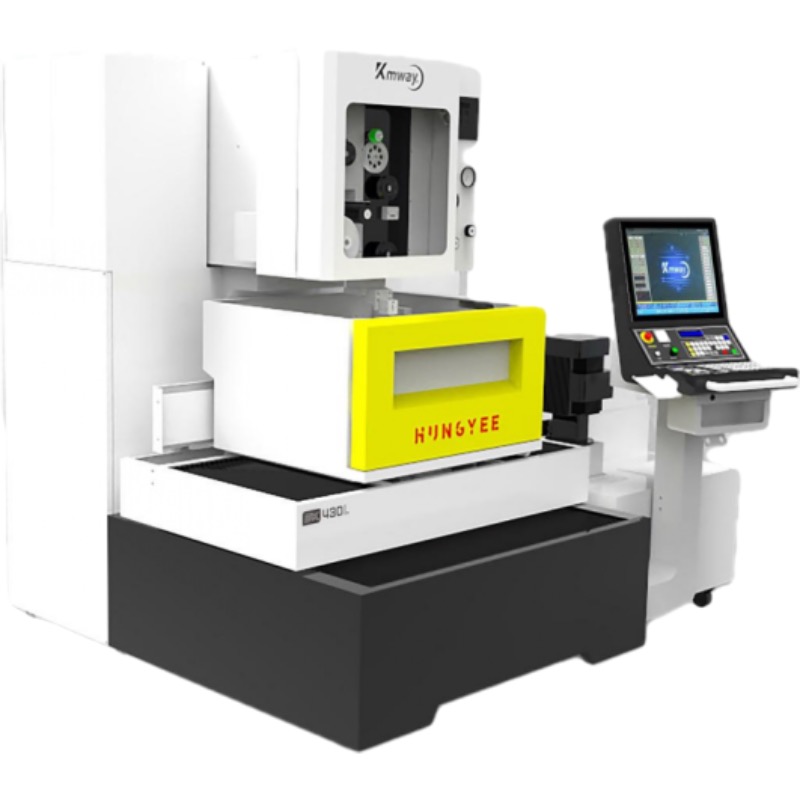

Advanced Wire WEDM Solutions

The Kmway EK430 Series WEDM Machines integrate the latest technological advancements from Taiwanese and Japanese engineering, ensuring unparalleled precision and efficiency in electrical discharge machining.

Robust Design and Features

Equipped with Chmer's eighth-generation discharge controller and an optional AWT system, the EK430 series promises consistent finishes and operational excellence.

Commitment to Innovation and Quality

Backed by a dedicated R&D team and robust after-sales support, Kmway's EK430 series is engineered to meet the rigorous demands of modern manufacturing environments.

Product Advantages

Advanced Control Technology: Incorporates Chmer's eighth-generation discharge controller, ensuring consistent finish, precision, and efficiency.

Enhanced AWT System: Features a third-generation AWT system with a high success rate, improving reliability and performance.

Robust Construction: Includes three vertical motors that offer safety, efficiency, and reduced maintenance costs.

Responsive After-Sales Support: Provides comprehensive dealer training and 24/7 customer support.

Versatile Machining Capabilities: Supports a wide range of wire diameters and has an efficient wire feed rate, suitable for various cutting needs.

Corporate Advantages

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

About US

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.