CK series comes standard with AWT system.

1. Kmway machines combine the advantages of Taiwanese machines and Japanese machines, mainly in synchronization with Chmer's eighth-generation discharge controller, with consistent finish, precision, and efficiency; the AWT system has learned the advantages of Japanese machines and has been updated to the third generation, with a conservative success rate of 95%; including our 3 vertical motors, which are safer and more efficient, less prone to breakdown, and lower maintenance costs.

2. Our service and after-sales team, our technicians can help customers answer questions online at any time. Although the normal working hours are from 8 am to 8 pm China time, when customers really have problems, no matter what time it is, we will try our best to help customers solve them quickly. Including our after-sales team, during dealer training, our after-sales engineers will list the problems and solutions that customers often encounter during use based on their rich experience to help dealers improve the quality of after-sales service.

3. Although Kmway is a new company, we have a strong R&D team (located in Hangzhou, Zhejiang, China). We pay great attention to customer feedback. As long as the customer raises a question, we will carefully study and give feedback, and we have been studying how to improve the efficiency of our machines. Now we have made the U series. There are few brands in the market that can make such a long-stroke machine and our price must be the most cost-effective, which can give customers more choices and there will be no shortage of supply.

Leading Precision in Wire EDM Technology

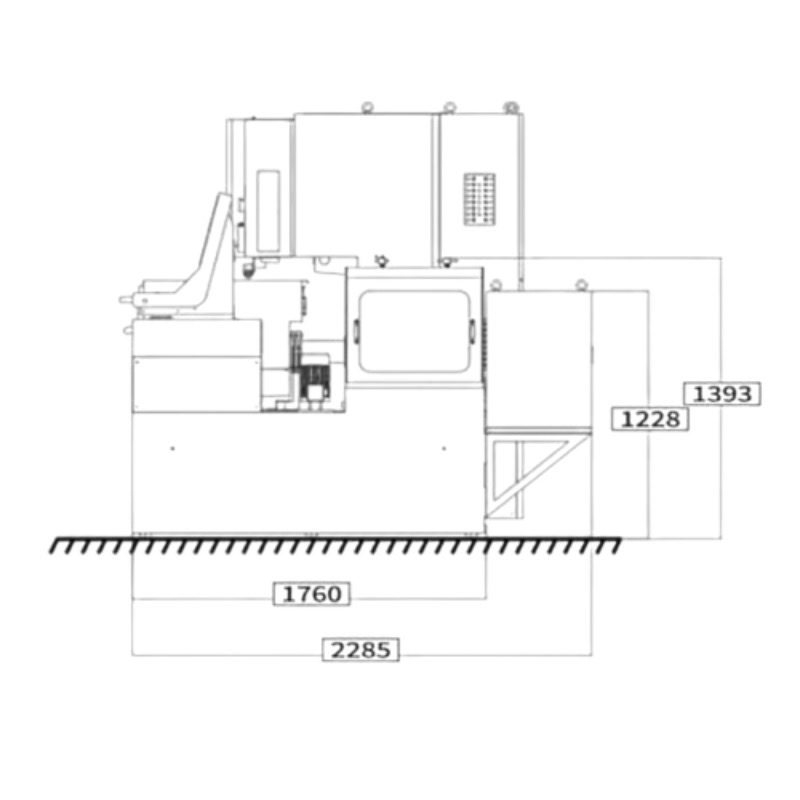

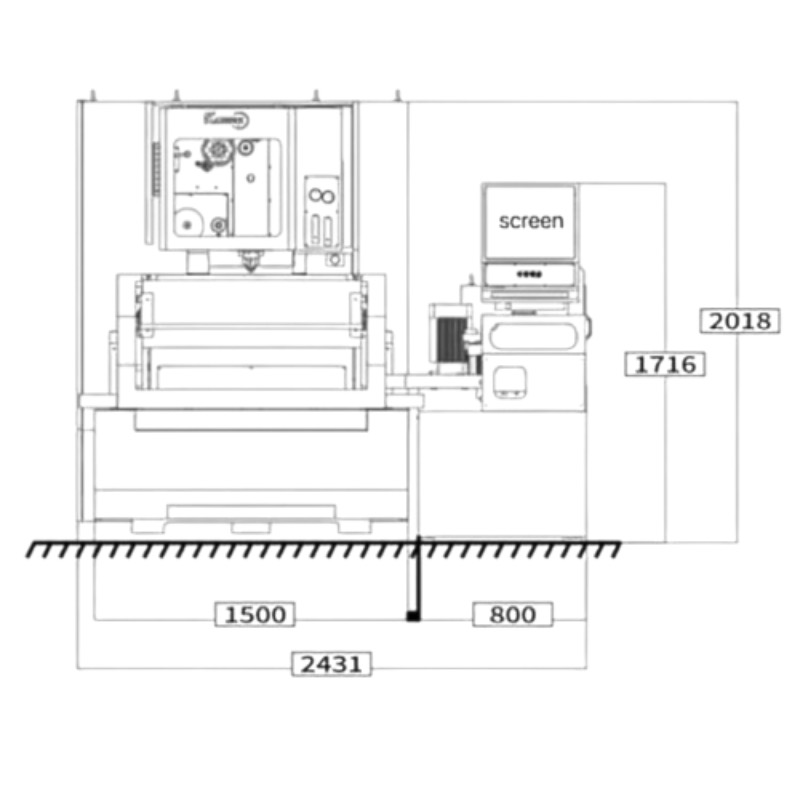

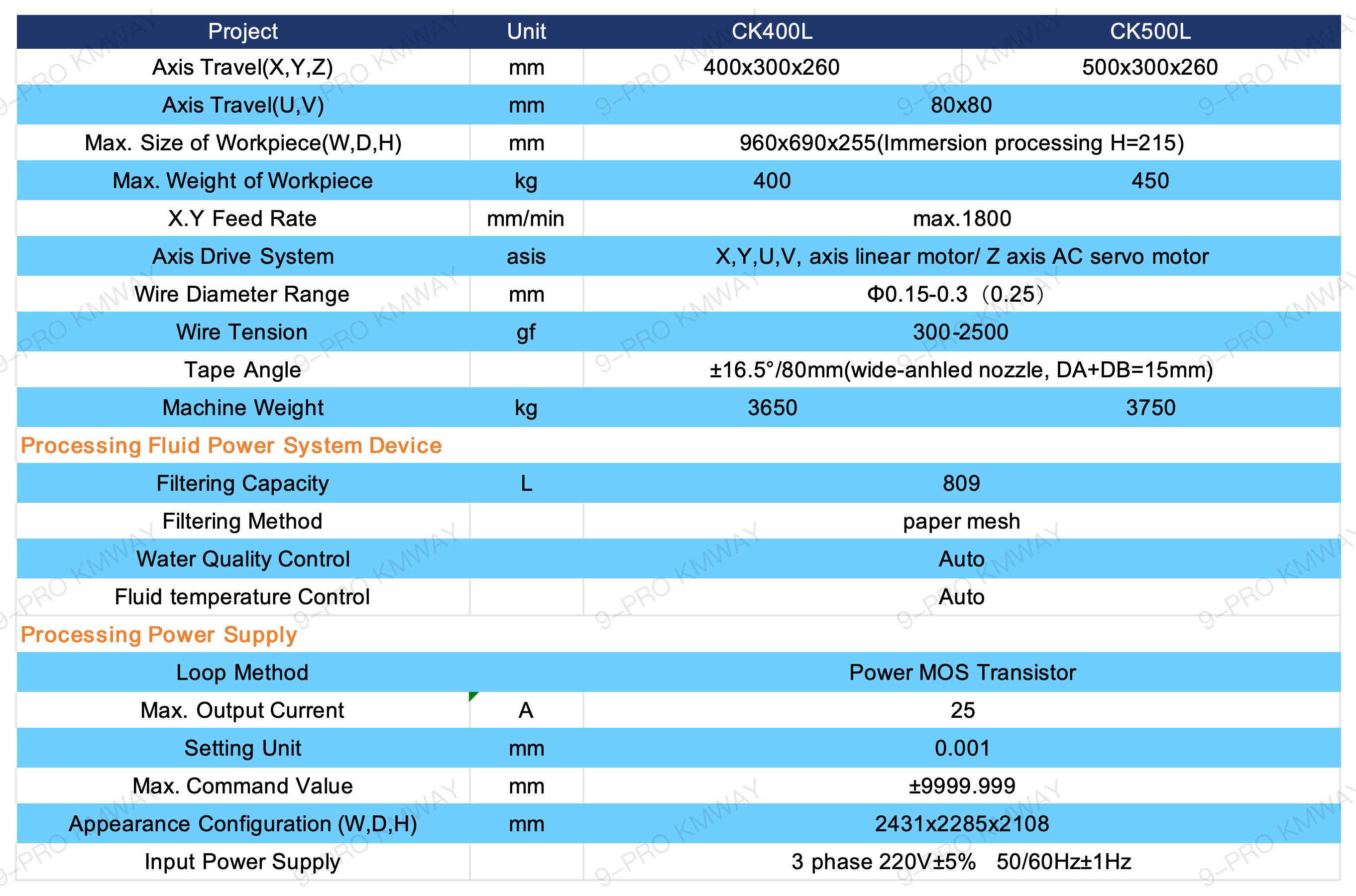

Unleash the full potential of your production with the CK400L/500L Series, integrating state-of-the-art technology for unmatched accuracy and speed in wire cutting.

Designed for the Industry's Best

These machines embody robust design and advanced control systems, offering exceptional functionality tailored for high-stake industries like aerospace and automotive manufacturing.

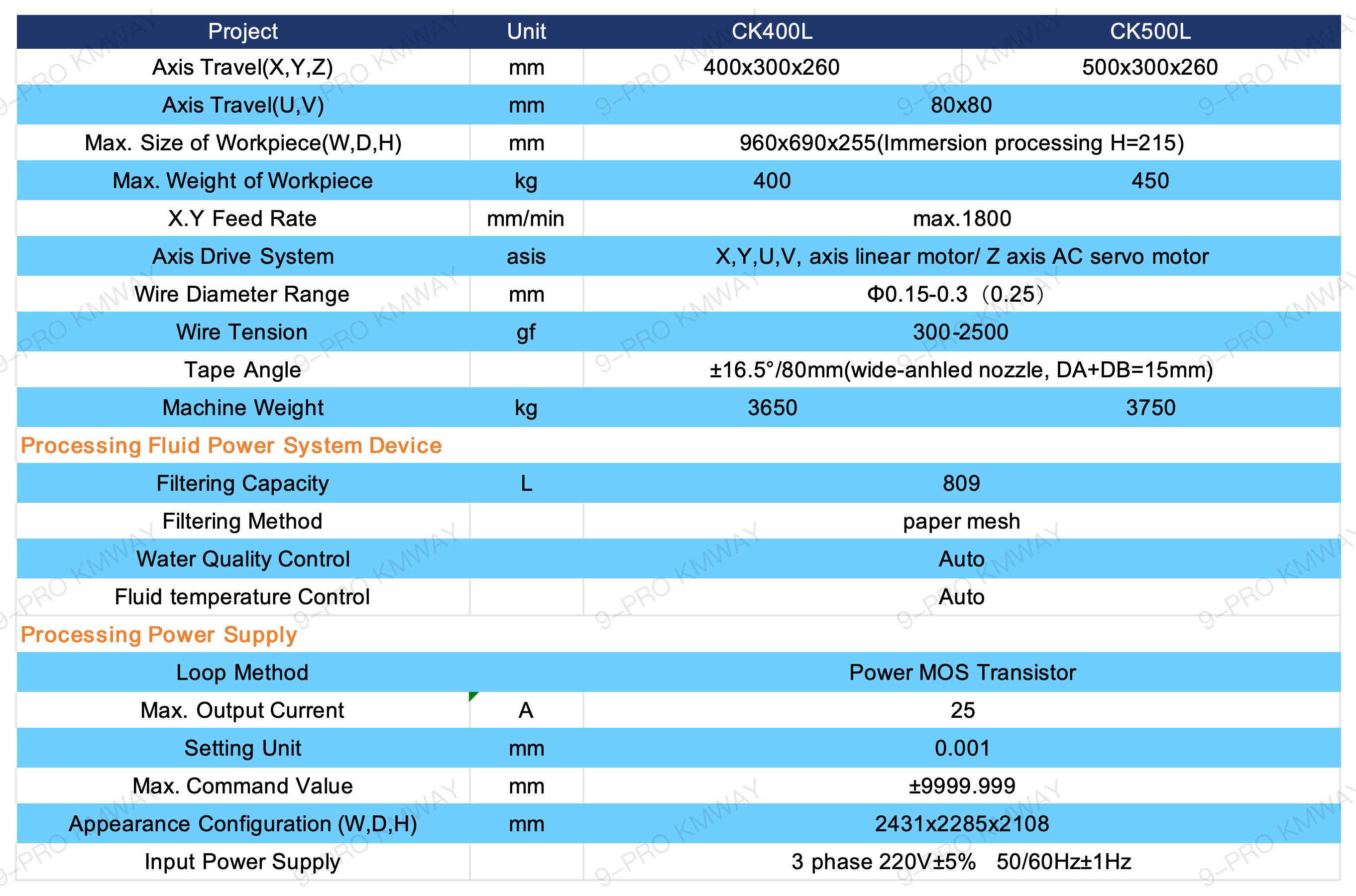

The CK400L/500L series from 9-Pro provides significant advantages for high-efficiency wire electrical discharge machining (WEDM):

Advanced AWT System: Features a third-generation Automatic Wire Threading (AWT) system with a high success rate of 95%, enhancing reliability and reducing downtime.

Superior Control Technology: Integrates with Chmer's eighth-generation discharge controller for consistent high finish, precision, and efficiency, matching the performance of top-tier machines.

Durable and Safe Design: Equipped with three vertical motors that ensure safer, more efficient operations and lower maintenance costs.

Robust After-Sales Support: This includes a dedicated service team available for online support outside of normal working hours to quickly resolve any issues and ensure continuous operation.

Corporate Advantages

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

About US

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.