In the fast-paced world of manufacturing, precision cutting is not just a luxury—it's a necessity. Whether you're crafting intricate components for the aerospace industry or producing high-quality tools, the need for accuracy and efficiency cannot be overstated. Kmway WEDM, a leading wire-cut machine manufacturer, ensures you achieve these exacting standards.

The Key Features of Kmway EK Series Wire-cut Machines

How Kmway WEDM Machines Enhance Cutting Precision

Maximizing the Efficiency of Your WEDM Machine

This is where Kmway WEDM (Wire Electrical Discharge Machining) machines come into play. Renowned for their exceptional cutting precision and innovative features, Kmway WEDM machines are transforming the way industries approach cutting processes.

The Key Features of Kmway EK Series Wire-cut Machines

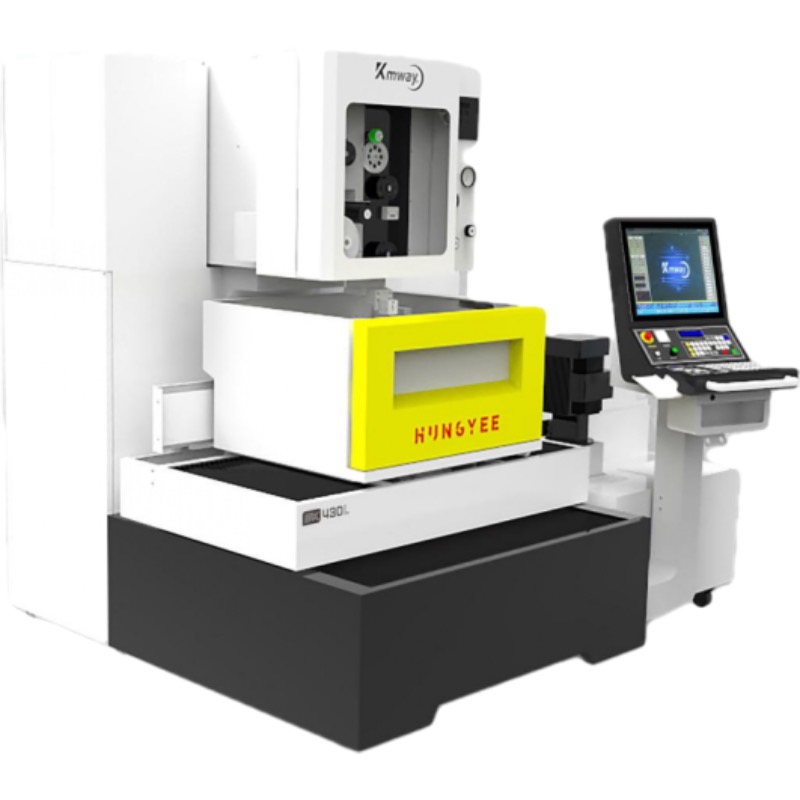

Kmway's EK Series Wire-cut Machines are designed with cutting-edge technology to meet the diverse needs of modern manufacturers. One standout feature is the high-speed processing capability, which ensures quick and efficient operations without compromising on precision. Additionally, these machines are equipped with advanced control systems that allow for seamless programming and operation, making them user-friendly even for those new to WEDM. The EK Series also boasts a robust build quality, ensuring durability and long-term reliability. With features like automatic wire threading and anti-electrolysis functionality, Kmway's EK Series reduces downtime and maintenance costs, further enhancing productivity.

How Kmway WEDM Machines Enhance Cutting Precision

Precision is the hallmark of . By utilizing a fine wire electrode, these machines can achieve extremely tight tolerances and intricate details that are essential for high-precision components. The advanced control systems in Kmway WEDM machines allow for precise adjustments in cutting parameters, ensuring consistency and accuracy in every cut. Furthermore, the machines' ability to operate in a stable and controlled environment minimizes the risk of thermal distortion, which can affect the quality of the cut. By maintaining a high level of precision, Kmway WEDM machines help manufacturers produce superior products that meet stringent industry standards.

Maximizing the Efficiency of Your WEDM Machine

Efficiency is crucial in maximizing the return on investment for any machinery, and Kmway WEDM machines are no exception. To get the most out of your Kmway WEDM machine, it's important to follow best practices for operation and maintenance. Regularly calibrating the machine and keeping it clean will ensure optimal performance and longevity. Additionally, utilizing the machine's advanced features, such as automatic wire threading and real-time monitoring, can significantly reduce setup times and increase overall productivity. Training operators to understand and leverage these features will further enhance efficiency and minimize downtime. By prioritizing efficiency, manufacturers can achieve higher output and better quality products, ultimately leading to increased profitability.

In conclusion, Kmway WEDM machines offer a powerful solution for industries requiring high-precision cutting. With their advanced features, superior precision, and efficiency-enhancing capabilities, these machines are a valuable asset for any manufacturing operation. By investing in Kmway WEDM machines, businesses can improve their cutting processes, reduce operational costs, and produce high-quality products that meet the demands of today's competitive market. If you're looking to elevate your manufacturing capabilities, consider exploring the benefits of Kmway WEDM machines and experience the difference they can make.