In today's fast-paced manufacturing world, precision and efficiency are more critical than ever. Innovations in Wire-cut Electrical Discharge Machining (EDM) technology have revolutionized how industries approach complex machining tasks. At the forefront of this technological evolution is Kmway, a premier Wire-cut EDM machine manufacturer.

Recent Advances in Kmway WEDM Machine Design

How Our Machines Lead the Market in Wire-cut Innovation

The Benefits of Using Advanced Kmway Wire-cut Machines

This post dives into the recent advances in Kmway WEDM machine design, highlighting why our machines lead the market in wire-cut innovation and the numerous benefits they offer.

Recent Advances in Kmway WEDM Machine Design

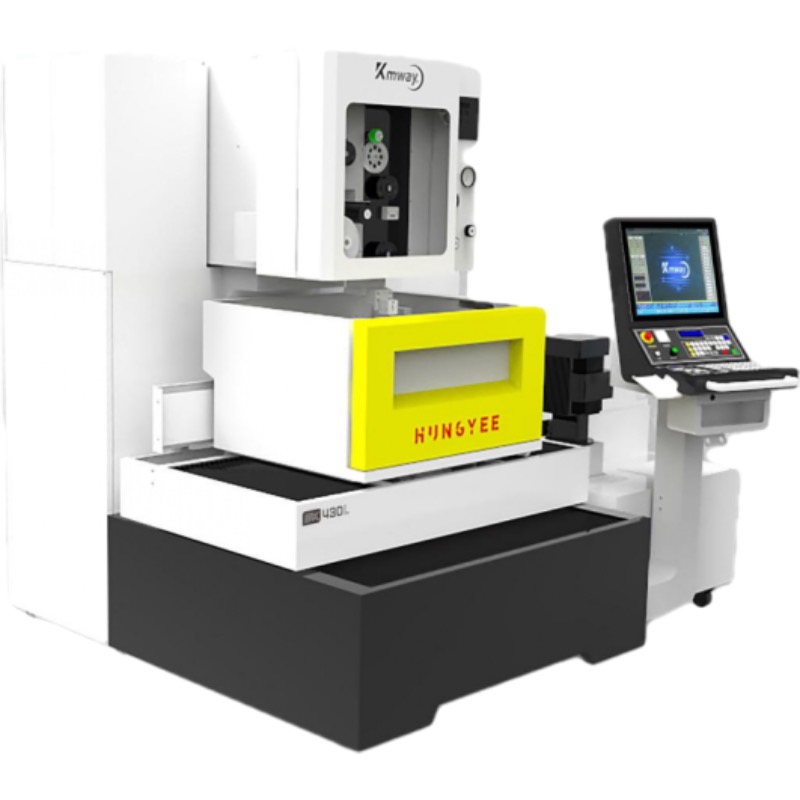

Kmway has always been committed to pushing the boundaries of Wire-cut EDM technology. Our latest models, including the EK430F, EK430S, and EK430L, epitomize this ethos. These machines incorporate state-of-the-art features designed to enhance precision, speed, and reliability. One notable advancement is the introduction of our dual servo motor design. This innovation ensures smoother and more accurate wire feeding, which significantly reduces wire breakage and downtime. Additionally, our new WEDM machines come equipped with advanced cooling systems that maintain optimal operating temperatures, thereby extending the lifespan of the machine components. Such design enhancements not only improve the overall performance but also contribute to cost savings by reducing maintenance needs.

How Our Machines Lead the Market in Wire-cut Innovation

Kmway's Wire-cut EDM machines stand out in the highly competitive market due to our relentless focus on innovation. We have integrated cutting-edge software that allows for real-time monitoring and adjustments during the machining process. This feature is particularly beneficial for industries requiring high precision, as it ensures that each cut adheres to the tightest tolerances. Furthermore, our machines are designed with user-friendly interfaces, making them accessible to operators of all skill levels. This ease of use, coupled with our comprehensive training programs, means that businesses can quickly integrate our machines into their production lines without a steep learning curve. Our commitment to continuous improvement and customer feedback has enabled us to develop machines that not only meet but exceed industry standards.

The Benefits of Using Advanced Kmway Wire-cut Machines

The advantages of using Kmway's advanced Wire-cut EDM machines are manifold. Firstly, our machines offer unparalleled precision, making them ideal for producing intricate components used in aerospace, medical, and automotive industries. The high level of accuracy reduces material waste and ensures consistent quality, which is crucial for maintaining competitive advantage. Secondly, the increased efficiency of our machines translates to shorter production times, allowing businesses to meet tight deadlines without compromising on quality. This efficiency is further enhanced by our machines' robust design, which minimizes downtime and maintenance requirements. Lastly, Kmway's Wire-cut EDM machines are not just tools but integral components of a comprehensive manufacturing solution. We provide ongoing support and updates, ensuring that our clients always have access to the latest advancements in EDM technology.

In conclusion, Kmway's Wire-cut EDM technology represents the pinnacle of precision and innovation in the manufacturing industry. Our recent advances in machine design, coupled with our market-leading features, make our machines the preferred choice for businesses seeking to enhance their machining capabilities. By choosing Kmway, companies can enjoy the numerous benefits of our cutting-edge technology, from improved accuracy and efficiency to reduced operational costs. Ready to take your manufacturing processes to the next level? Discover the Kmway advantage today.