In the world of Electrical Discharge Machining (EDM), the quality and functionality of filters can significantly impact the performance and longevity of machines. Whether you're an industrial heavyweight or a small-scale operation, understanding the key features of top-tier EDM filters is crucial. Today, we'll be examining three exemplary models from 9-PRO, a renowned EDM parts manufacturer—PR-05, NH-09, and NH-09D filters.

Detailed Overview of PR-05, NH-09, and NH-09D Specifications

The Role of High-Quality Filters in EDM Machine Performance

Comparing PR-05, NH-09, and NH-09D to Other EDM Filters

This comprehensive guide will provide a detailed overview of their specifications, the role of high-quality filters in EDM machine performance, and a comparison against other filters in the market.

Detailed Overview of PR-05, NH-09, and NH-09D Specifications

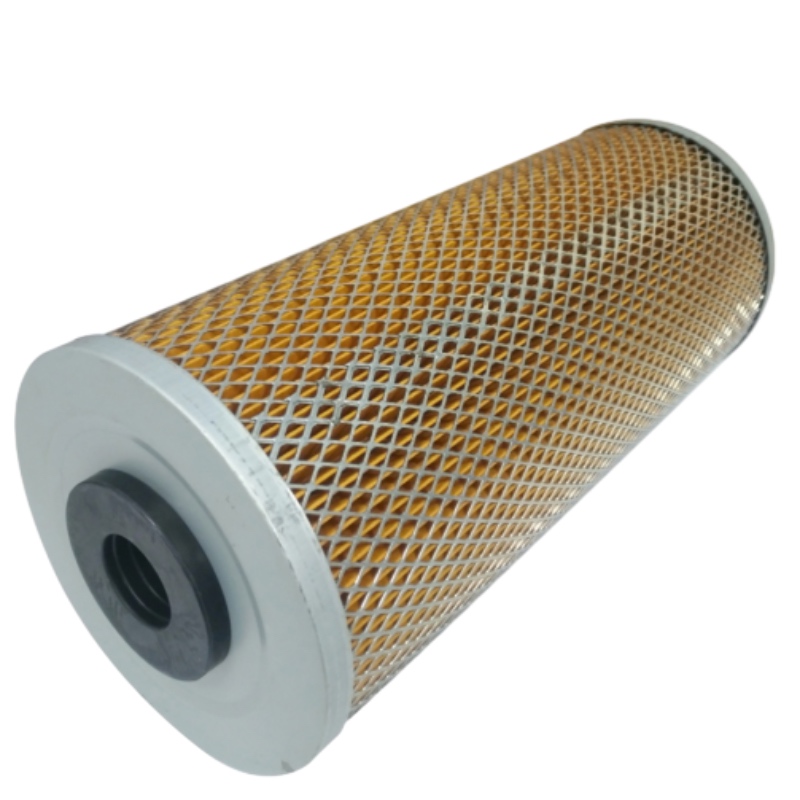

The PR-05 filter from 9-PRO, an EDM parts manufacturer, stands out with its exceptional filtration efficiency and durability. Made from high-grade materials, it boasts a filtration capacity that rivals some of the best in the industry. With a pore size designed to capture even the smallest particulates, the PR-05 ensures that your EDM machine runs smoothly without the risk of clogging or damage. Similarly, the NH-09 model is engineered for high performance. It features a multi-layer filtration system that effectively separates contaminants from the dielectric fluid. This model is particularly known for its extended lifespan, reducing the frequency of filter changes and thereby minimizing downtime. The NH-09D takes it a step further by integrating advanced filtration technology that not only captures contaminants but also enhances fluid flow. This results in a more efficient electrical discharge process, leading to better surface finishes and higher precision in machining operations.

The Role of High-Quality Filters in EDM Machine Performance

High-quality filters like the PR-05, NH-09, and NH-09D play a pivotal role in maintaining the optimal performance of EDM machines. These filters are designed to remove contaminants from the dielectric fluid, which is essential for the EDM process. Contaminants can cause a range of problems, from poor surface finishes to complete machine failure. By effectively removing these impurities, high-quality filters ensure that the dielectric fluid remains clean and efficient, thereby enhancing the overall performance of the EDM machine. Furthermore, using superior filters reduces the wear and tear on the machine components. When contaminants are not adequately filtered, they can cause abrasive wear on the machine parts, leading to frequent maintenance and replacements. High-quality filters extend the life of the machine, providing better value for money in the long run. Another critical aspect is the impact on production quality. Clean dielectric fluid ensures consistent electrical discharges, which is vital for achieving precise cuts and excellent surface finishes. This consistency translates to higher production quality, meeting the stringent standards required in industries such as aerospace, automotive, and medical device manufacturing.

Comparing PR-05, NH-09, and NH-09D to Other EDM Filters

When compared to other EDM filters available in the market, the PR-05, NH-09, and NH-09D models from 9-PRO, an EDM parts manufacturer, demonstrate superior performance and reliability. Many filters fail to match the multi-layer filtration system of the NH-09, which ensures a thorough separation of contaminants, resulting in cleaner fluid and better machine performance. Additionally, the advanced filtration technology in the NH-09D sets it apart from standard filters. While many filters focus solely on removing impurities, the NH-09D enhances fluid flow, contributing to a more efficient EDM process. This dual functionality makes it an invaluable asset for any EDM operation. The PR-05 also excels when compared to other filters, particularly in terms of durability and filtration capacity. Its ability to capture finer particulates ensures that even the smallest contaminants are removed, protecting the machine and enhancing its performance.

In conclusion, the PR-05, NH-09, and NH-09D filters from 9-PRO are exemplary models that highlight the importance of high-quality filtration in EDM machines. These filters not only enhance machine performance but also contribute to better production quality and extended machine life. For businesses looking to optimize their EDM operations, investing in these top-tier filters is a decision that will pay dividends in the long run. To learn more about how these filters can benefit your operations, visit our website and explore our range of EDM parts and accessories.