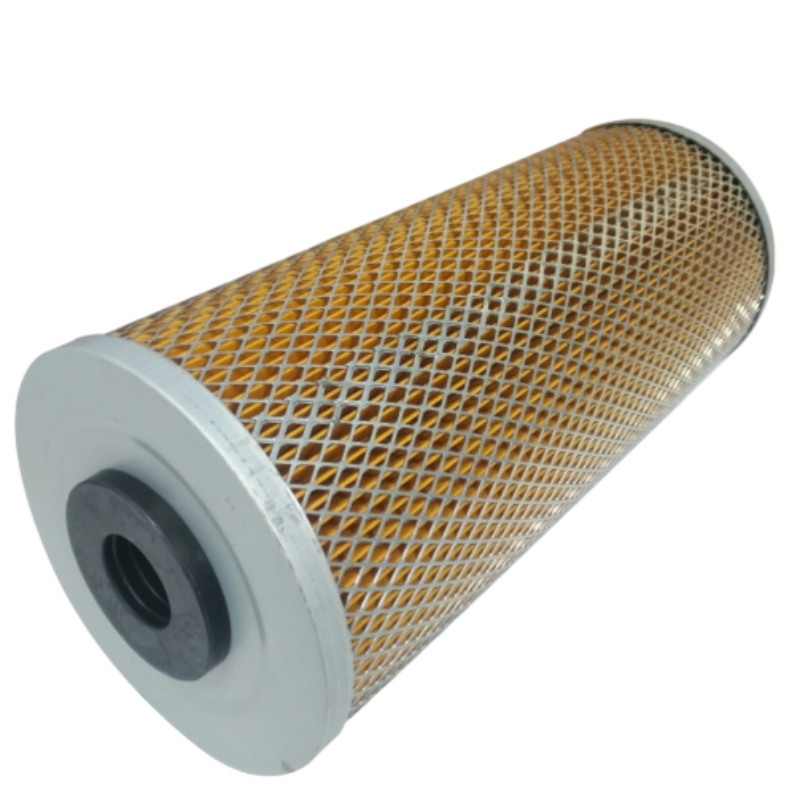

Explore the Precision of PR-05 NH-09 NH-09D EDM Filters

Optimize your EDM equipment's performance with our high-precision filters, engineered for compatibility with multiple machine models.

Why Choose PR-05 NH-09 NH-09D?

With superior filtration capabilities, our EDM filters ensure cleaner operations and reduced wear and tear on your machines.

Technical Specifications

- Dimensions: 150mm x 33mm x 360mm

- Compatible with Models: M20, M25 series, and more

- Pressure Handling: Engineered for high-demand environments

Enhanced Operational Efficiency

Our filters are designed not just to protect but to improve the efficiency of your EDM processes, ensuring smooth operations and higher productivity.

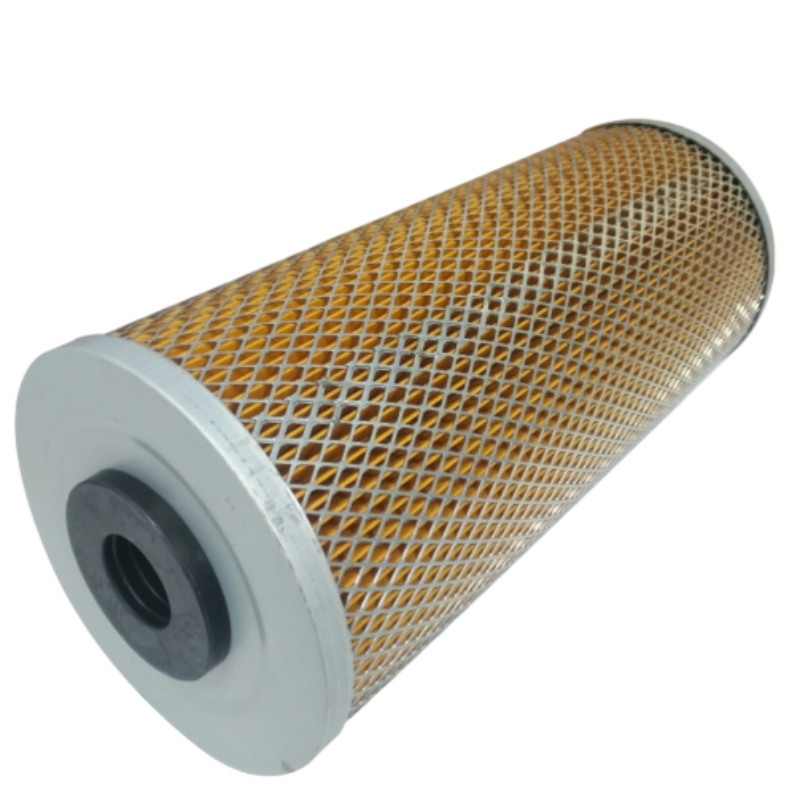

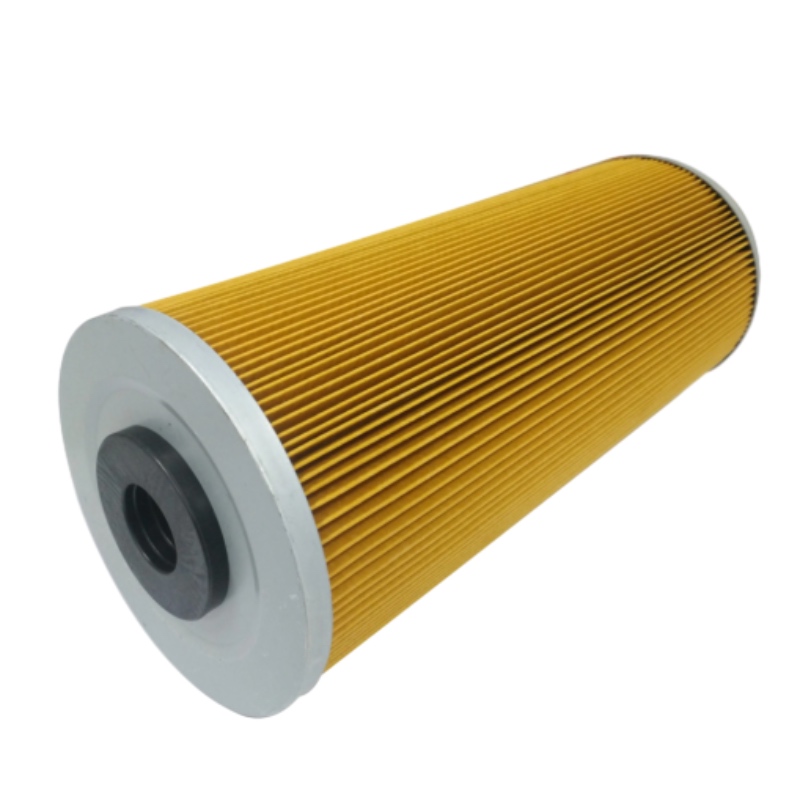

Code No.:PR-05 EDM Filter

Code No.:PR-05 EDM Filter

Dimensions:ф150*ф33*360mm

Material:Filter Paper, Polyester, And Metal

Core Components:High Quality Filter Paper

Weight:1.30kg

Packing:2 filters per carton

Application Machines Brand:SODICK, MITSUBISHI, CHMER, AGIE, CHARMILLES, HITACHI, JOEMARS, CASTEK

Advantages

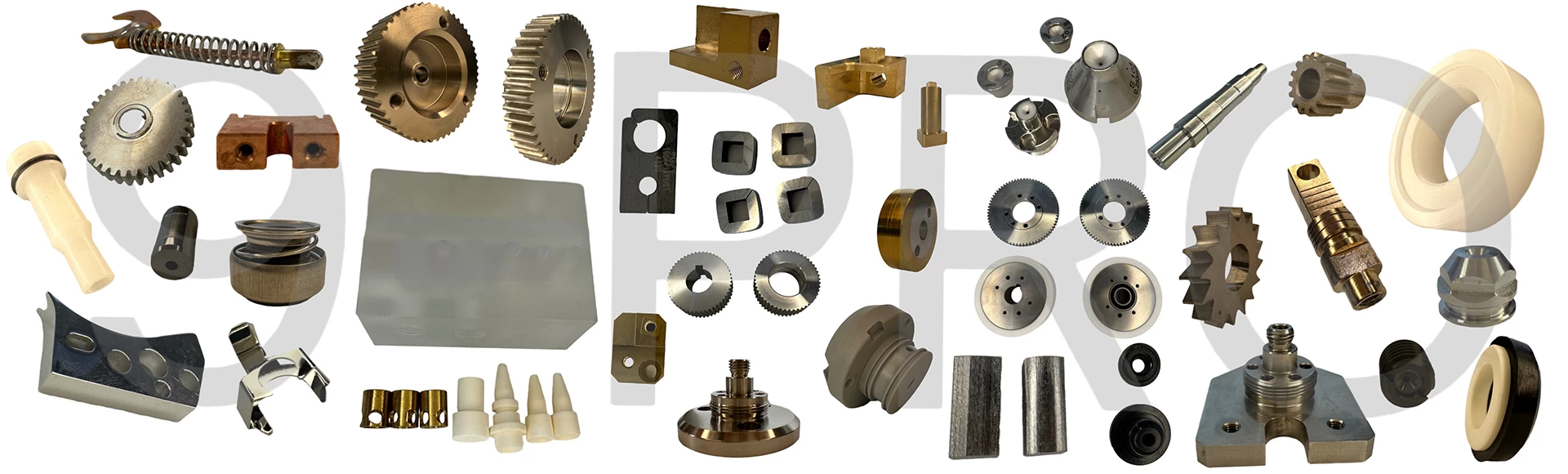

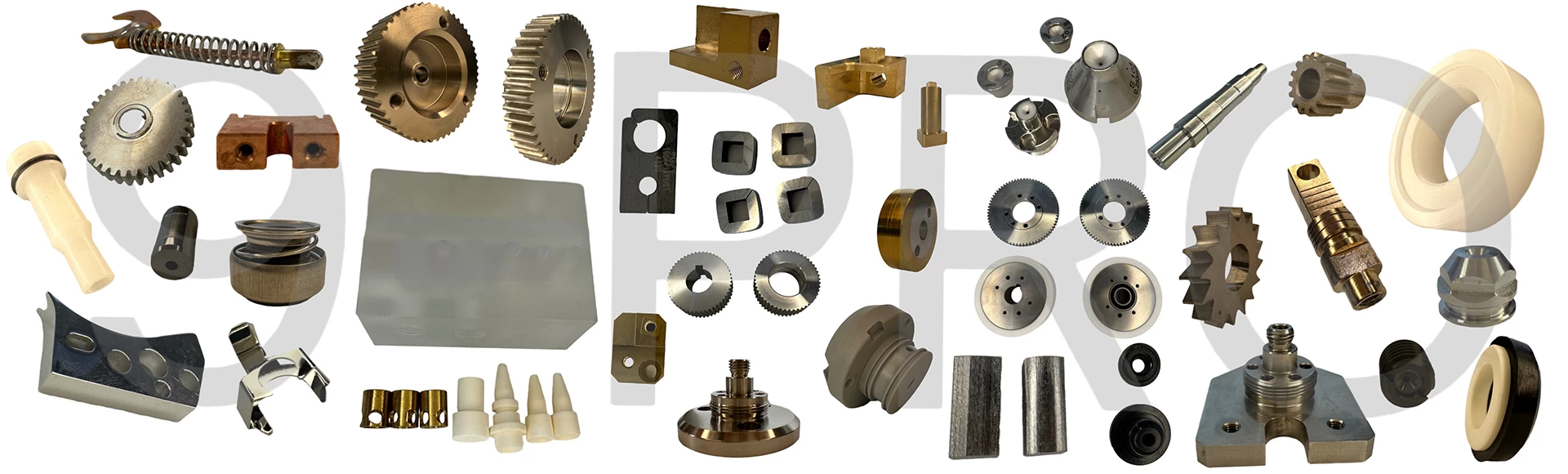

Commitment: 9-PRO demonstrates a strong commitment to quality and customer satisfaction, focusing on providing high-quality EDM wires and machine parts tailored to precise machining needs.

Capability: The company showcases its capabilities in producing a wide range of EDM products and parts, indicating a robust manufacturing and supply operation aimed at meeting diverse and specific industry requirements.

For more detailed information, please visit 9-PRO's website.

Why choose PR-05 NH-09 NH-09D?

Our EDM filters provide superior filtration capabilities, ensuring cleaner operation and reduced wear on your machines.

1. Metal mesh is woven from metal filaments, and divided into square mesh and twill mesh. It has small flow resistance and can be used in a very high-temperature range. Strong cleaning ability and long service life.

2. It has a high-performance filter element structure: a high-strength, pollution-free, burr-free, and chemical-reactive inner skeleton; the internal and external support nets should be of sufficient strength, pollution-free, burr-free, and chemical-reactive;

3. The filter element must be produced in a dust-free workshop, generally reaching a level of 100,000, and the testing test must be conducted in a clean laboratory of level 1,000. The filter material of the filter element is generally made into a corrugated shape. It is worth noting that if the filter element flows from outside to in, the corrugated folds should be close to the inner frame; if the filter element flows from inside to out, the corrugated folds should be close to the outer frame.

4. Nowadays, filter elements are tested according to ISO standards. The relevant standards are as follows: structural integrity test; compatibility test of materials and media; rupture resistance test; rated axial load test; pressure drop flow characteristic measurement; flow fatigue characteristic test; and multiple-pass testing of filtration performance.

5. Appearance quality refers to the appearance impression given by the filter element after it is made, mainly including: whether the processing smoothness and surface treatment of the upper and lower covers are beautiful; whether the corrugation of the filter material is uniform and whether it is perpendicular to the upper and lower covers; whether the adhesive on the upper and lower covers, filter material, and longitudinal seams of the filter material is appropriate.

FAQ

1. Who are we?

9-PRO is a manufacturer with over 8 years of experience, specializing in wire EDM.

2. How can we guarantee quality?

We guarantee quality through strict quality control processes.

3. What can you buy from us?

Customers can buy various EDM wires and parts.

4. Why should you buy from us not from other suppliers?

9-PRO distinguishes itself by providing reliable products, extensive industry experience, and strong R&D capabilities.

5. What services can we provide?

We offer customized product solutions and comprehensive after-sales services.

For detailed answers, please visit their FAQ page.

About US

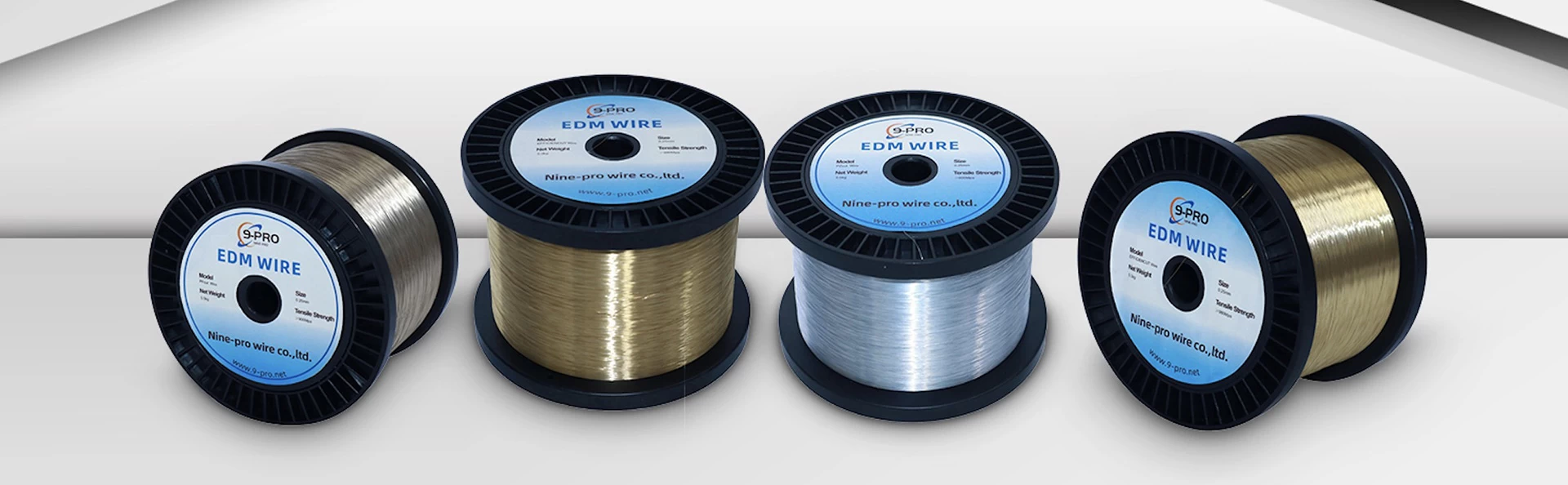

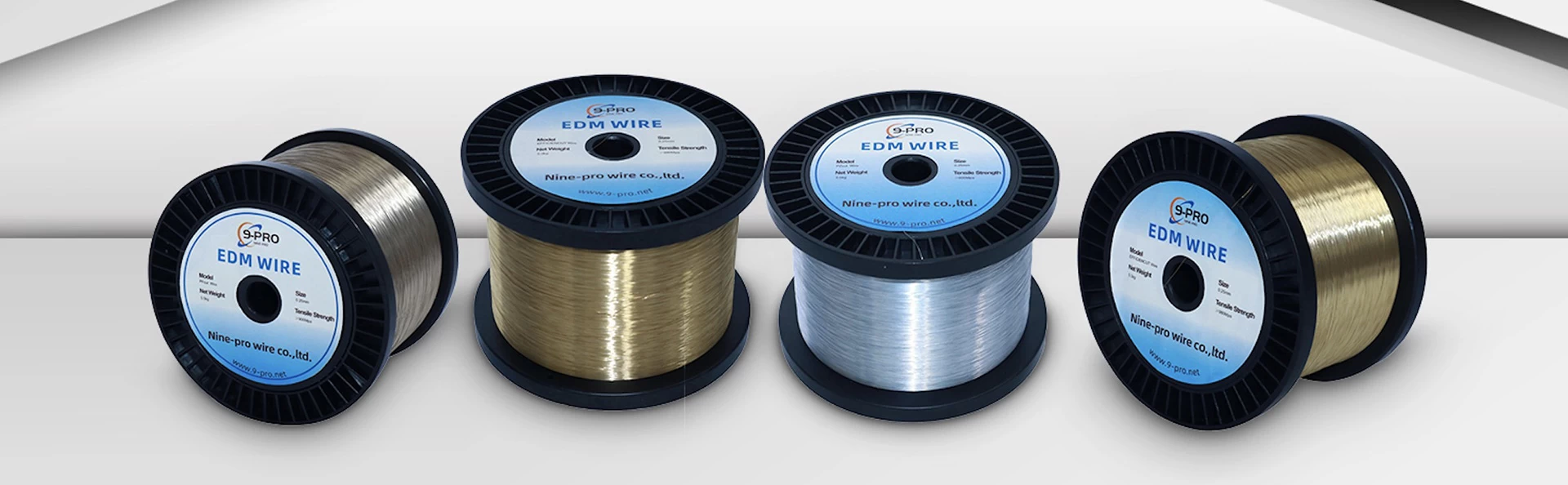

Nestled in the vibrant coastal area of Zhejiang Province, 9-PRO stands as a testament to innovation and dedication in the field of EDM wire manufacturing.

With over eight years of experience, the company weaves a story of precision, passion, and performance. It's not just about the 4000 tons of annual production capacity or the distribution of 200 tons of EDM wire each month; it's about the relentless pursuit of excellence and the commitment to pushing the boundaries of what's possible in EDM technology. This narrative is not just their history; it's a promise to their customers and a vision for the future.

For more about their journey and ethos, visit 9-PRO's Company Page.