Are you tired of spending hours trying to achieve that perfect surface finish on your machined parts? Do you struggle with ensuring consistency and precision in every finished product? Look no further, as we delve into the world of Electrical Discharge Machining (EDM) wires and its potential to revolutionize the surface finishing process. In this blog post, we will explore how EDM wires can help you achieve superior results with minimal effort, giving your products a flawless appearance and increasing their value. Whether you’re an engineer looking for ways to improve efficiency or a business owner seeking cost-effective solutions, read on to discover how EDM wires can benefit your manufacturing process.

1.Key Factors Influencing Surface Finish in EDM Machining

2.Strategies for Achieving High-Quality Finishes in EDM

3.Balancing Speed and Surface Finish with Advanced EDM Wires

1.Key Factors Influencing Surface Finish in EDM Machining

When it comes to EDM machining, achieving the desired surface finish is crucial. There are several key factors that can influence the surface finish, such as the type of material being machined, the electrode design, and the EDM Wire used. The EDM Wire used is particularly important, as it can impact the overall quality and consistency of the surface finish. Factors such as the wire diameter, material composition, and tension can all play a role in determining the final result. By carefully considering all of these factors, manufacturers can ensure that they are producing high-quality parts with accurate surface finishes.

2.Strategies for Achieving High-Quality Finishes in EDM

When it comes to achieving high-quality finishes in EDM, there are several strategies to consider. EDM wire, for instance, can play a critical role in ensuring that the final result meets or exceeds your expectations. By using a finer wire, you can increase the precision of the cuts and reduce the amount of material that needs to be removed in the finishing process. Additionally, adjusting the voltage and current settings on your EDM machine can help to achieve a smoother surface finish on your workpiece. It's important to keep in mind that achieving a high-quality finish requires attention to detail and a willingness to experiment with different settings and techniques until you find the one that works best for your specific needs. With the right approach and tools at your disposal, you can achieve exceptional results that will impress even the most discerning clients or customers.

3.Balancing Speed and Surface Finish with Advanced EDM Wires

When it comes to wire-electrical discharge machining (EDM), manufacturers often face the challenge of balancing speed and surface finish. They require a process that is both efficient and effective in achieving the desired results. Enter advanced EDM wires, which offer improved conductivity and precision during the machining process. These wires are designed to provide optimal electrical discharge and reduce cutting time, while maintaining high levels of surface finish quality. With the use of advanced EDM wires, manufacturers can achieve the perfect balance between speed and precision, resulting in high-quality end products that meet their customers' expectations.

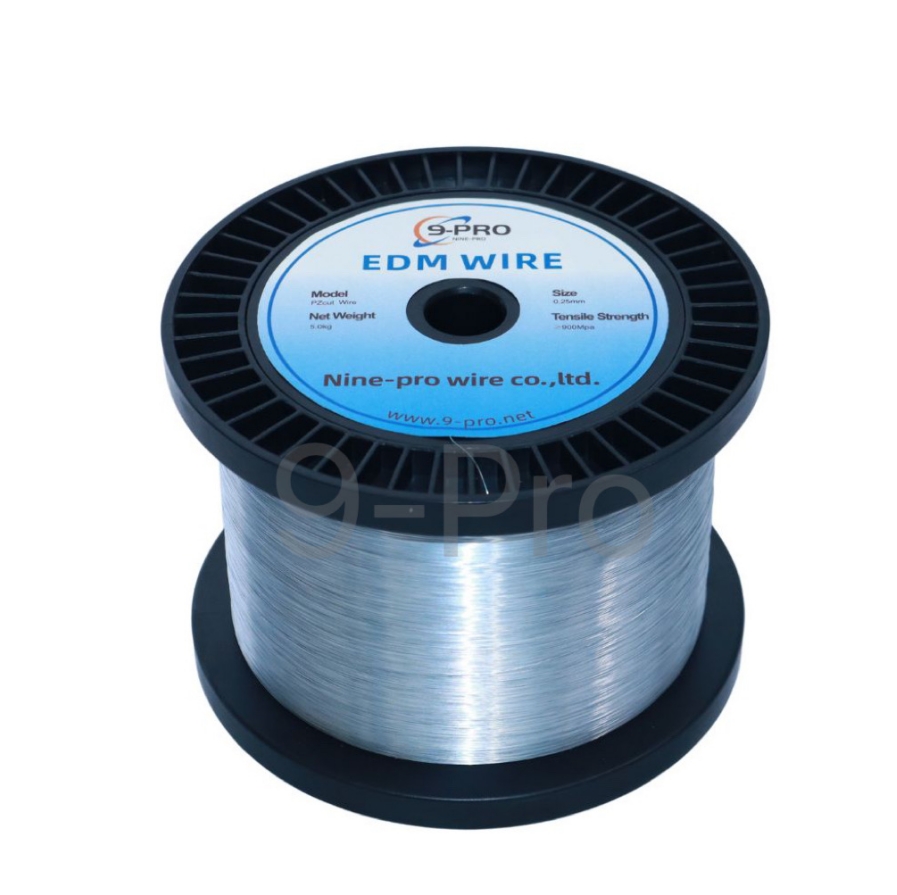

In conclusion, it is clear that achieving high-quality surface finishes in EDM machining requires a thorough understanding of the key factors influencing the process. From material selection to tooling and machine settings, every aspect must be carefully considered and optimized to achieve the desired finish. However, with the advancements in EDM wire technology, there are now ways to balance speed and surface finish without compromising on either aspect. By choosing a reliable and advanced EDM wire supplier like 9-PRO, you can ensure that your machining processes are efficient and produce top-notch finishes. Don't settle for subpar results when it comes to surface finish – make the right choice for your business's success by partnering with 9-PRO today. With their expertise and cutting-edge products, you can take your EDM machining to new heights and deliver exceptional results for your customers. So don't wait any longer – improve your surface finishes and elevate your business by choosing 9-PRO as your EDM wire supplier. Your customers will thank you for it!