In the world of manufacturing, cost efficiency is paramount. With the rapid advancements in technology, enterprises are constantly on the lookout for innovative methods to reduce expenses while maintaining high standards. Enter PF CUT EDM Wires, a groundbreaking solution that promises to revolutionize the way we approach manufacturing.

How PF CUT EDM Wires Can Help Reduce Manufacturing Costs

Comparing the Cost-Effectiveness of Different EDM Wire Types

Maximizing the Value of Your PF CUT EDM Wire Investment

Case Studies: Cost Savings Achieved with PF CUT EDM Wires

This blog post will explore how PF CUT EDM Wires can significantly reduce manufacturing costs, compare its cost-effectiveness with other EDM wire types, showcase case studies of cost savings, and provide valuable insights for maximizing your investment. For business professionals and manufacturers, this could be the game-changer you've been waiting for.

How PF CUT EDM Wires Can Help Reduce Manufacturing Costs

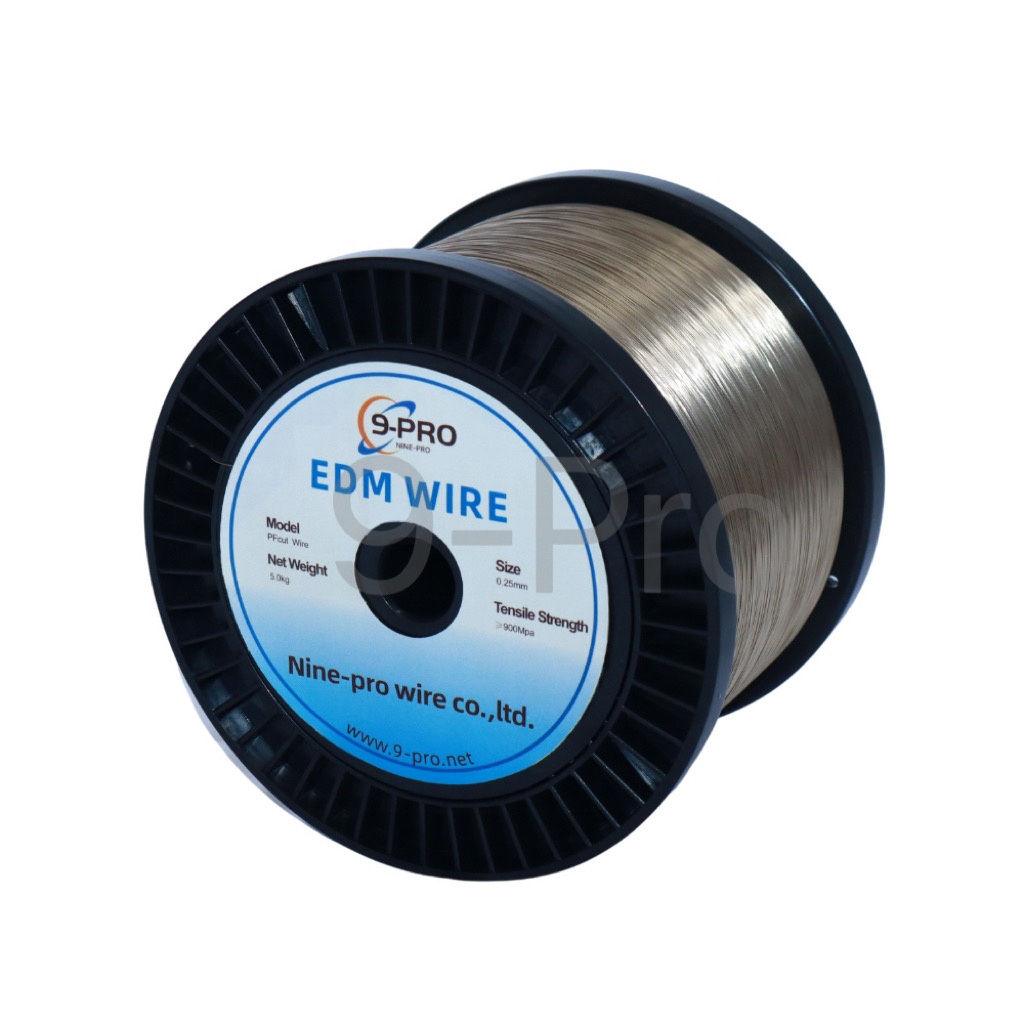

PF CUT EDM Wires, particularly those from 9-Pro, are designed to offer high-speed precision machining. One of the standout features is their ability to cut difficult-to-machine materials such as tungsten and graphite at a speed 20% higher than standard brass wires. This increased cutting speed translates to reduced machine time, which directly impacts labor costs and overall production efficiency. Additionally, the superior cleanliness of PF CUT EDM Wires means less wear and tear on machine components, resulting in lower maintenance costs and extended machine life. By choosing PF CUT EDM Wires, manufacturers can achieve significant cost savings without compromising on quality or performance.

Comparing the Cost-Effectiveness of Different EDM Wire Types

When it comes to EDM wires, not all are created equal. Traditional copper/zinc EDM wires, while effective, often fall short in terms of speed and cleanliness compared to PF CUT EDM Wires. High-speed PF CUT wires outperform typical copper/zinc wires (composed of 63% copper and 37% zinc) by not only cutting faster but also burning cleaner. This efficiency reduces the need for other EDM consumables like filters and rails, thereby cutting down on recurrent expenses. Furthermore, the smooth surface of PF CUT EDM Wires makes them ideal for automatic threading, which adds another layer of cost-efficiency by minimizing manual intervention. In essence, investing in PF CUT EDM Wires can lead to long-term financial benefits by streamlining operations and reducing consumable costs.

Maximizing the Value of Your PF CUT EDM Wire Investment

To get the most out of your PF CUT EDM Wire investment, it's essential to understand the various ways you can optimize their use. First, ensure that your machines are compatible with high-speed PF CUT wires. This includes regular maintenance to keep your equipment in top condition, which will maximize the wire's performance. Second, take advantage of the detailed cutting instructions and tips provided by manufacturers like 9-Pro to ensure you're using the wires most efficiently. Lastly, consider bulk purchasing options. 9-Pro offers various shaft sizes, including 5kg, 8kg, and 10kg, with immediate shipping available for some sizes and reasonable lead times for others. Buying in bulk can secure better pricing and ensure a steady supply, further enhancing the cost-effectiveness of your operations.

Case Studies: Cost Savings Achieved with PF CUT EDM Wires

Numerous manufacturers have already experienced significant cost savings by switching to PF CUT EDM Wires. For instance, a precision tooling company specializing in tungsten reported a 25% reduction in overall production costs within six months of adopting PF CUT wires. They attributed the savings to faster cutting speeds and reduced machine downtime. Another case involved a manufacturer of high-end automotive parts. By switching to PF CUT EDM Wires, they noticed a marked improvement in the cleanliness of cuts, which led to fewer defects and a decrease in wastage costs. These real-world examples highlight the tangible benefits of choosing PF CUT EDM Wires, making them an invaluable asset for any forward-thinking manufacturer.

In today's competitive manufacturing landscape, finding cost-effective solutions is more critical than ever. PF CUT EDM Wires offer an exceptional blend of speed, precision, and cleanliness, making them a superior choice for reducing manufacturing costs. By investing in these advanced wires, businesses can optimize their operations, minimize downtime, and enjoy long-term financial benefits. If you're looking to enhance your manufacturing efficiency while maintaining high standards, it's time to consider PF CUT EDM Wires from 9-Pro. Sign up for our service today and experience the difference for yourself. For more information about PF CUT EDM Wires, visit 9-Pro's official website.