Electrical Discharge Machining (EDM) is a critical technology in precision manufacturing, and the innovation in EDM wires is indispensable to its evolution. For manufacturers, staying abreast of these advances is key to maintaining a competitive edge.

Recent Innovations in EDM Wire Technology

The Future of EDM Wire Design Trends and Predictions

Advances in Materials Used for EDM Wires

This blog post dives deep into the latest innovations and technological advancements in EDM wires, exploring how they are reshaping the industry. We will also highlight the cutting-edge materials enhancing EDM wire performance and provide insights into future trends. Whether you are an EDM wires manufacturer, a supplier interested in wholesale EDM wires, or a professional seeking to understand the latest in EDM technology, this comprehensive guide is tailored for you.

Recent Innovations in EDM Wire Technology

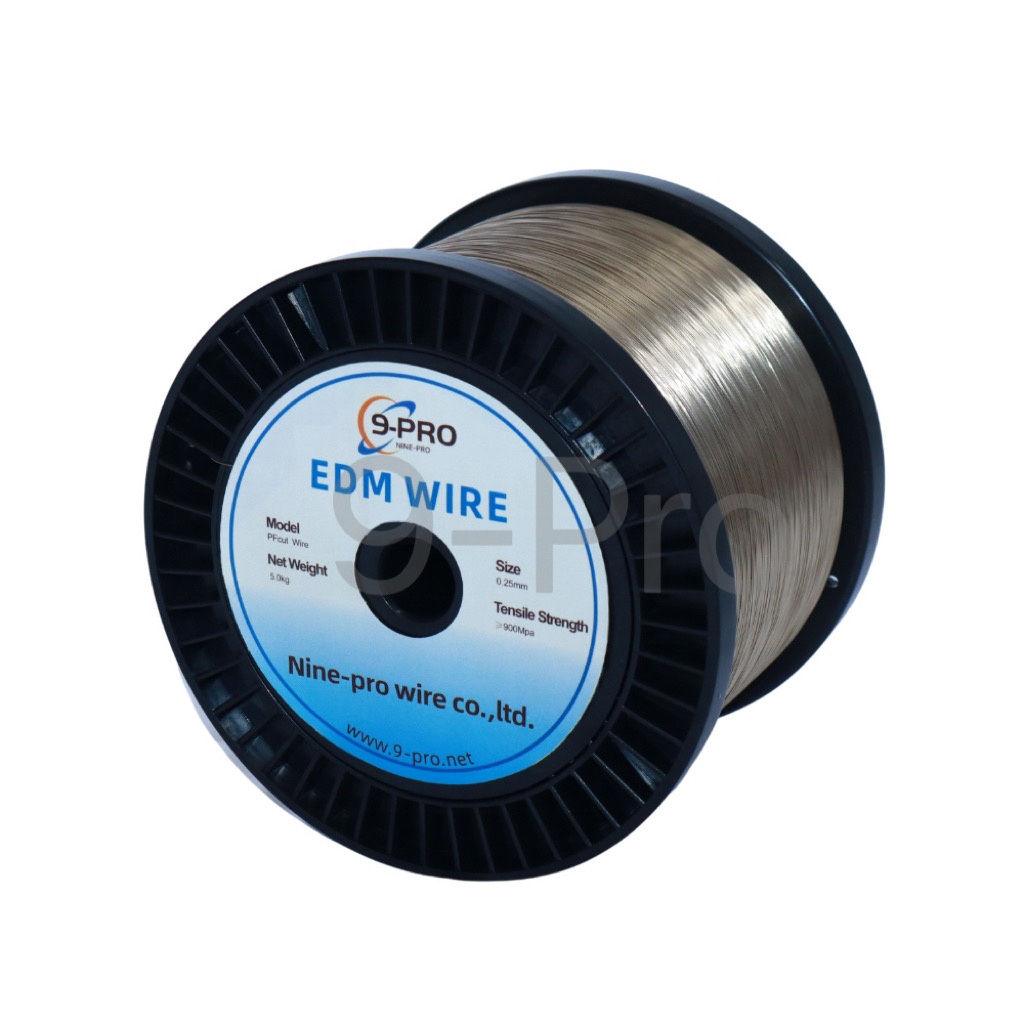

The landscape of EDM wire technology is rapidly evolving, thanks to continuous research and development. Among the most notable innovations is the introduction of high-speed coated EDM wires like the Nine-Pro PFcut Wire series. This wire is designed to offer a 20% higher cutting speed compared to traditional brass wires, significantly enhancing productivity. The PFcut Wire also excels in machining challenging materials such as tungsten and graphite, providing superior cleanliness and reducing the need for additional consumables. This innovative wire not only cuts faster but also burns cleaner, making it a cost-effective choice for manufacturers. Another noteworthy advancement is the development of wires with improved surface smoothness, facilitating automated threading and ensuring consistent performance across various machining tasks.

The Future of EDM Wire Design Trends and Predictions

Looking ahead, the future of EDM wire design promises even more groundbreaking advancements. One of the emerging trends is the focus on sustainability and environmental impact. Manufacturers are increasingly developing wires that are not only high-performing but also eco-friendly, utilizing materials and processes that minimize environmental footprint. Additionally, the integration of smart technology into EDM wires is set to revolutionize the industry. Imagine wires embedded with sensors that provide real-time data on performance, wear, and tear, enabling predictive maintenance and reducing downtime. Another exciting prediction is the customization of EDM wires for specific applications, allowing manufacturers to tailor their tools precisely to their needs. This level of customization will lead to more efficient and effective machining processes, further solidifying the role of EDM technology in advanced manufacturing.

Advances in Materials Used for EDM Wires

Material science plays a crucial role in the ongoing enhancement of EDM wires. Recently, there has been significant progress in developing new materials that offer superior performance characteristics. High-speed coated wires like the Nine-Pro PFcut Wire Series are a prime example, combining advanced coatings with high-quality core materials to achieve exceptional cutting speeds and precision. Innovations in composite materials have also led to wires that are more durable and capable of withstanding higher temperatures, extending their lifespan and reducing the frequency of replacements. Additionally, research into nano-materials is opening up new possibilities for EDM wires that are lighter, stronger, and more conductive than traditional options. These advancements in materials are driving the industry forward, offering manufacturers tools that deliver unmatched performance and efficiency.

The innovations and technological advancements in EDM wires are transforming the landscape of precision manufacturing. From high-speed coated wires like the Nine-Pro PFcut to emerging trends in smart technology and eco-friendly designs, the future of EDM wire technology is bright and full of potential. For businesses looking to stay ahead of the curve, understanding these developments is crucial. By investing in advanced EDM wires, manufacturers can enhance their productivity, reduce costs, and achieve higher levels of precision in their machining processes. If you're interested in learning more about the latest in EDM wire technology or looking for the best options for your business, consider reaching out to a reputable EDM wires manufacturer like 9Pro. Their expertise and commitment to quality can help you find the ideal solutions for your specific needs.