Displaying items by tag: Fanuc

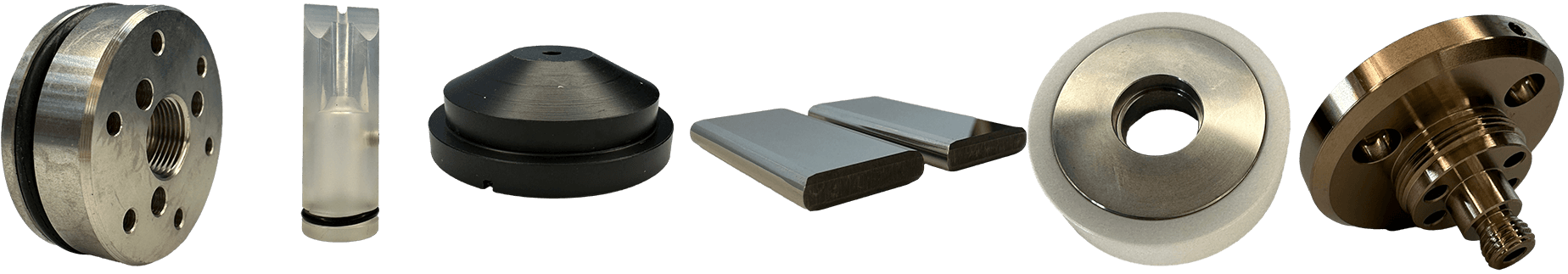

Fanuc Wire EDM Wire Guide Block F8911 A290-8110-Y770

9-Pro Fanuc Wire EDM Wire Guide Block F8911/A290-8110-Y770 - Elevate Your EDM Accuracy

The 9-Pro Fanuc Wire EDM Wire Guide Block (F8911/A290-8110-Y770) is expertly crafted to provide unparalleled precision in wire cutting operations. Built for Fanuc EDM machines, this guide block ensures optimal wire alignment, resulting in clean and precise cuts. Designed with durability in mind, it reduces downtime and enhances the longevity of your equipment, making it the perfect addition for professionals seeking reliability and accuracy in their machining processes.

Key Features of the 9-Pro Fanuc EDM Wire Guide Block

Precision Engineering: The wire guide block is designed to provide exact alignment of the EDM wire, ensuring flawless and accurate cuts with minimal material waste.

Durable Construction: Made from high-quality materials, the guide block is built to withstand the demands of continuous EDM operations, providing long-lasting reliability and reducing the need for frequent replacements.

Seamless Compatibility: Specifically designed for Fanuc EDM machines, the F8911/A290-8110-Y770 wire guide block ensures perfect integration with your existing setup, enhancing operational efficiency.

Cost-Effective Solution: By improving wire cutting accuracy and minimizing downtime, this guide block helps reduce operational costs, offering excellent value for high-performance EDM applications.

Choose 9-Pro’s Fanuc Wire EDM Wire Guide Block for your wire-cut EDM machine and experience the difference in performance and durability. Trusted by professionals, our parts are designed to help you achieve precise and efficient machining results.

| Commodity | Wire guide block 69*51*20mm |

|---|---|

| Number | F8911 |

| OEM Numbers | A290-8110-Y770 |

| Packing Quantity | 1 pc(s) |

| Machine Type |

Fanuc a-0C with AWF, a-0C without AWF, a-iA with AWF, a-iA without AWF, a-0iB with AWF, a-iB without AWF, a-iC with AWF, a-0iC without AWF, a-1C with AWF, a-1C without AWF, a-liA with AWF, a-liA without AWF, a-liB with AWF, a-1iB without AWF, Fanuc a-1iC with AWF, a-1iC without AWF |

| Application | Wire-cut EDM |

| Category | Housings |

Product Advantages

Precision Alignment for Accurate Cutting

The 9-Pro Fanuc Wire EDM Wire Guide Block ensures exact wire alignment during electrical discharge machining (EDM) operations, resulting in precise and clean cuts with minimal errors.

Seamless Compatibility with Fanuc EDM Machines

Designed specifically for Fanuc EDM machines, this wire guide block integrates smoothly with your existing equipment, ensuring flawless operation and enhancing overall machine performance.

Durable and Long-Lasting

Manufactured from high-quality materials, the guide block is built to withstand the rigors of continuous industrial use, offering exceptional durability and reducing the need for frequent replacements.

Increased Operational Efficiency

By maintaining wire alignment and ensuring accurate cuts, this guide block reduces material waste and operational downtime, helping to improve productivity in your manufacturing processes.

Cost-Effective Solution

With its precision and durability, the 9-Pro Fanuc EDM Wire Guide Block contributes to lower maintenance costs and increased longevity of your equipment, providing an excellent return on investment for industrial applications.

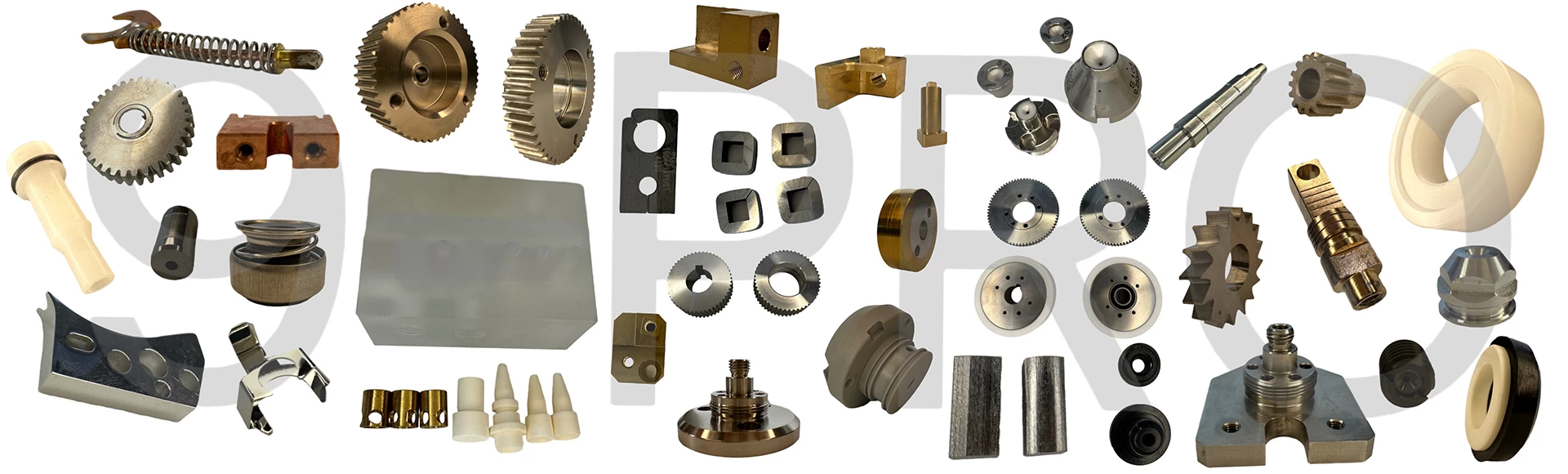

About Us

At 9-Pro, we believe in precision, reliability, and innovation. Our journey began with a singular vision: to become the leading provider of high-quality EDM parts and components for the global manufacturing industry. Today, we are proud to be a trusted partner for businesses worldwide, offering a comprehensive range of cutting-edge EDM solutions that drive efficiency and enhance performance.

Our Story: From Vision to Global Impact

Founded with a passion for excellence, 9-Pro started as a small but ambitious company dedicated to meeting the demands of the fast-growing Electrical Discharge Machining (EDM) industry. Recognizing the need for highly accurate and durable parts, we set out to create products that would exceed expectations in terms of precision, durability, and cost-efficiency.

Over the years, we have continuously evolved, investing in advanced manufacturing technologies and expanding our product lines to cater to a diverse array of industrial needs. Our dedication to research and development has allowed us to stay ahead of the curve, delivering solutions that meet the ever-changing demands of the industry.

What Sets Us Apart

At 9-Pro, we don't just manufacture EDM parts – we innovate for the future. Our commitment to quality and customer satisfaction drives every decision we make, ensuring that each product we deliver is of the highest standard.

Here’s what makes us unique:

Unparalleled Precision: Every 9-Pro product is engineered with the finest tolerances, ensuring superior performance and longevity in even the most demanding applications.

Trusted by Industry Leaders: Our clients range from small-scale manufacturers to global corporations, all of whom trust 9-Pro for reliable and high-performance EDM parts.

Continuous Innovation: We are constantly exploring new materials, technologies, and methods to improve our product offerings, staying at the forefront of the EDM industry.

Our Mission: Empowering Your Success

Our mission is simple: to provide you with the tools and solutions you need to succeed. We understand that precision and reliability are key to your business, and we are committed to delivering products that help you achieve the highest levels of performance and efficiency. Whether it's custom EDM parts or off-the-shelf solutions, 9-Pro is here to help you take your business to the next level.

Join us on this journey of precision and innovation, and let’s shape the future of manufacturing together.

9-Pro – Precision You Can Trust.

Fanuc Wire EDM Machining Roller A290-8004-X713 F413

A290-8004-X713 Pinch or urethane roller and oullev have the features of high quality materials, precious grinding, goodconcentricity, small beating. stable wire transport. high hardness and long working life for low speed wire cut EDM machines

Commodity: Roller Φ49*D6*6mm

Number: F413

OEM numbers: A290-8004-X713

Packing quantity: 1 pc(s)

Machine type: Fanuc O, P, Q, R. T. W0, W1 with AWF. W1 without AWF. W2 with AWF. W2 without AWF. W3 with AWF. W3 without AWF .W4 with AWF. W4 without AWF

Application: Wire-cut EDM

Category: Rollers

Fanuc EDM wear parts F423 A290-8119-X618 Brake shoe upper

Fanuc EDM Brake Shoe Upper: Enhanced Durability and Precision

Maximize the efficiency of your electrical discharge machining with our Fanuc EDM Brake Shoe Upper. This essential wear part, model F423 A290-8119-X618, is crafted to provide unmatched durability and precision, ensuring your EDM equipment operates at peak performance. Ideal for demanding industrial environments, it ensures a prolonged lifespan and reduces the need for frequent replacements.

Key Features and Specifications

Our Fanuc EDM Brake Shoe Upper boasts features that enhance your machine's performance. Made with high-grade materials, it withstands rigorous use and maintains precise control. Compatibility with various Fanuc EDM models ensures seamless integration. Upgrade today and experience the 9-Pro advantage in your manufacturing processes.

F423 A290-8119-X618 Brake shoe upper Fanuc EDM wear parts

Number: F423

OEM Number: A290-8119-X618

Size: OD100 x ID20 x T22mm

Brand: Fanuc

Product Description: F423 A290-8119-X618 Brake shoe upper Fanuc EDM wear parts EDM Consumables, Power EDM

Machine Model: Fanuc α-0iD with AWF, Fanuc α-0iD without AWF, Fanuc α-0iE with AWF, Fanuc α-0iE without AWF, Fanuc α-1iD with AWF, Fanuc α-1iD without AWF, Fanuc α-1iE with AWF, Fanuc α-1iE without AWF, Fanuc α-C400iA with AWF, Fanuc α-C400iA without AWF, Fanuc α-C400iB with AWF, Fanuc α-C400iB without AWF, Fanuc α-C600iA with AWF, Fanuc α-C600iA without AWF, Fanuc α-C600iB with AWF, Fanuc α-C600iB without AWF, Fanuc α-C800iA with AWF, Fanuc α-C800iA without AWF, Fanuc α-C800iB with AWF, Fanuc α-C800iB without AWF

Product Advantages

Precision Engineering: Designed specifically for Fanuc machines, ensuring compatibility and optimal performance.

Durability: Made with high-quality materials to withstand the rigorous demands of continuous EDM operations.

Improved Performance: Enhances the efficiency and accuracy of EDM machines by maintaining stable and precise control during operations.

Cost-Effective: Reduces the need for frequent replacements and maintenance, providing a long service life.

Easy Installation: Engineered for easy and quick installation, minimizing downtime and maximizing productivity.

About US

Nestled in the heart of Ningbo City, Zhejiang Province, 9-PRO stands as a beacon of innovation in the realm of EDM wire and machine parts. Our journey began over a decade ago with a single mission: to elevate the standards of EDM components worldwide. Today, 9-PRO is synonymous with precision and reliability, serving manufacturers across the globe.

At 9-PRO, we believe in the power of technology to transform industries. Each wire and part that leaves our facility embodies our commitment to excellence. Our in-house production ensures that every component is crafted to the highest specifications, making your EDM operations seamless and efficient.

Your challenges inspire our innovations. By continuously evolving our technology and processes, we aim to provide not just parts but solutions that enhance your productivity and profitability. At 9-PRO, your success is our priority, and we are dedicated to supporting you at every step of your manufacturing journey.

Join us as we continue to push the boundaries of what is possible in EDM machining. With 9-PRO, experience precision where it matters most.

For more details, visit our website.

FAQ

Who are we?

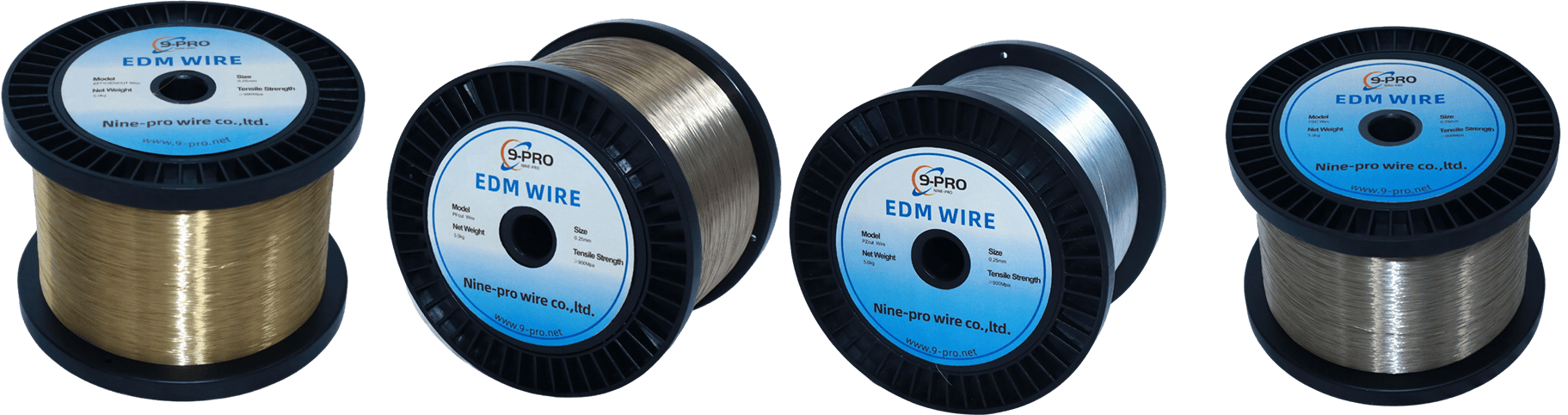

We are a provider of direct EDM wire and parts supply services to manufacturers worldwide, specializing in wire EDM accessories.

How can we guarantee quality?

Quality is assured through complete in-house production and strict testing of accuracy and hardness for each part, maintaining a quality control standard of 1/500.

What can you buy from us?

You can purchase a wide range of EDM wires, parts, and accessories, tailored to meet various manufacturing needs.

Why should you buy from us and not from other suppliers?

Our products are competitively priced and made with high-quality materials, we offer professional customization services for brand promotion.

What services can we provide?

We offer professional customized services, online video conferences to discuss needs, and welcome on-site inspections at our factory in Ningbo, China.

For more detailed information, you can visit our FAQ page.

Fanuc Wire EDM Pressure Roller A290-8110-X382 A290-8110-V384

A290-8110-X382.A290-8110-V384 Pirch or urethane roller and pullev have the features of high quality materials. preciousgrinding, good concentricity, small beating, stable wire transport, high hardness and long working life for low speed wire cut EDM machines.

Commodity: Pressure roller 40*28*30mm

Number: F403

OEM numbers: A290-8110-X382.A290-8110-V384

Packing quantity: 1 pc(s)

Machine type: Fanuc a-0C with AWF, Fanuc a-0C without AWF Fanuc a-1C with AWF. Fanuc a-1C without AWF

Application: Wire-cut EDM

Category: Rollers

Fanuc Wire EDM Machining Drive Roller A290-8112-X383 F406

A290-8112-X383 Pinch or urethane roller and pulley have the features of high quality materials, precious grinding, goodconcentricity, small beating, stable wire transport, high hardness and long working life for low speed wire cut EDM machines

Commodity: Drive roller $80 *25mm

Number: F406

OEM numbers: A290-8112-X383

Packing quantity: 1 pc(s)

Machine type: Fanuc a-0A with AWF, Fanuc a-0A without AWF, Fanuc a-0B with AWF, Fanuc a-0B without AWF. Fanuc a-0Cwith AWF. Fanuc a-0C without AWF. Fanuc a-OiA with AWF. Fanuc a-OiA without AWF, Fanuc a-1A with AWF, Fanuc a-lAwithout AWF. Fanuc a-1B with AWF. Fanuc a-1B without AWF. Faruc a-1C with AWF. Fanuc a-1C without AWF.Faruc a-1iAwith AWF Fanuc a-liA without AWF

Application: Wire-cut EDM

Category: Rollers

Fanuc AWF Wire EDM Drive Roller F404 A290-8110-X383

A290-8110-X383 Pinch or urethane roller and pulley have the features of high quality materials, precious grinding, goodconcentricity. small beating, stable wire transport. high hardress and long working life for low speed wire cut EDM machines

Commodity: Drive roller Φ40*30mm

Number: F404

OEM numbers: A290-8110-X383

Packing quantity: 1 pc(s)

Machine type: Fanuc a-0C with AWF, Fanuc a-0C without AWF, Fanuc a-1C with AWF, Fanuc a-1C without AWF

Application: Wire-cut EDM

Category: Rollers

Fanuc Drive Roller F402 A290-8101-X383 A290-8101-Y383 A290-8101-Z383

A290-8101-X383.A290-8101-Y383.A290-8101-7383 Pinch or urethane roller and pullev have the features of high qualitymaterials, precious grinding, good concentricity, small beating, stable wire transport, high hardness and long working life for lowspeed wire cut EDM machines

Commodity: Drive roller $40*912*19mm

Number: F402

OEM numbers: A290-8101-X383.A290-8101-Y383.A290-8101-Z383

Packing quantity: 1 pc(s)

Machine type: Fanuc a-0A with AWF. a-A without AWF. a-0B with AWF. a-0B without AWF. a-1A with AWF. a-lA withouAWF. a-1B with AWF. a-1B without AWF

Application: Wire-cut EDM

Category: Rollers

Fanuc Wire EDM Machining Insulation Block A290-8102-X600 F316

Commoditv: Insulation block 70 *27 *48mm

Number: F316

OEM numbers: A290-8102-X600

Packing quantity: 1 pc(s)

Machine type: Fanuc a-OiD with AWF, Faruc a-OiE with AWF, Fanuc a-liD with AWF.Fanuc a-liE with AWF. Fanuc a-400iAwith AWF.Fanuc a-C400iB with AWF. Fanuc a-C600iA with AWF. Fanuc a-C600iB with AWF.Fanuc a-C800iA with AWF. Fanuc a-C800iB with AWF

Application: Wire-cut EDM

Category: Isolater plates

Fanuc Wire Cutting Machine Guide Base F307 A290-8101-X761

Commodity: Guide base 66*56.5*75mm

Number: F307

OEM numbers: A290-8101-X761

Packing quantity: 1 pc(s)

Machine type: Fanuc a-0A with AWF Fanuc a-0A without AWF, Fanuc a-1A with AWF, Fanuc a-1A without AWF

Application: Wire-cut EDM

Category: Housings

Fanuc EDM wear parts F306 A290-8101-X312 A290-8110-X312 Isolation plate lower

F306 A290-8101-X312 A290-8110-X312 Isolation plate lower Fanuc EDM wear parts

Number: F306

OEM Number: A290-8101-X312 A290-8110-X312

Size: OD72 x T15mm

Brand: Fanuc

Product description: F306 A290-8101-X312 A290-8110-X312 Isolation plate lower Fanuc EDM wear parts EDM Consumables, Power EDM

Machine type: a-A/B/C series